In hydraulic systems, supercritical equipment, and power generation installations, the Anti-Extrusion Ring is a key component safeguarding primary sealing elements (such as O-rings and lip seals) against extrusion failure under high pressure. By providing rigid support, gap filling, and stress dispersion, it increases the pressure-bearing capacity of the sealing system by 5-10 times. This article systematically elaborates on the technical principles and engineering practices of anti-extrusion rings from four key dimensions: structural mechanics, material innovation, design calculation, and industry applications.

I. Core Mission: Solving High-Pressure Seal Failure

High-Pressure Seal Failure Mechanisms:

When system pressure exceeds the extrusion resistance of the primary seal:

Seal Material Creep: Rubber/PTFE flows into clearance gaps under pressure (e.g., O-ring extrusion initiates above >5 MPa).

Permanent Damage: Seal element shearing creates leakage paths.

Typical Failure Scenarios:

NBR O-Ring: 30% volume extrusion through a 0.1mm gap at 15 MPa.

PTFE V-Ring: Lip tearing occurs with a 0.05mm gap at 10 MPa.

Mechanical Intervention by Anti-Extrusion Rings:

Rigid Support: High-modulus materials (PEEK/metal) resist deformation, blocking pressure transfer to the primary seal.

Gap Filling: Precision-matching of seal cavity clearance (0.01~0.2mm) eliminates media intrusion paths.

Stress Dispersion: Angled designs convert point loads into distributed loads, reducing contact stress by 50%-70%.

II. Material Evolution: From Conventional Plastics to Composite Reinforcements

Performance Metrics of Key Materials:

PTFE: Compressive strength 25 MPa, temp range -200°C to 260°C, friction coefficient 0.05~0.10. Suitable for low-pressure corrosive environments (<35 MPa).

Filled PTFE: Compressive strength 40~60 MPa, temp range -200°C to 260°C, friction coefficient 0.08~0.15. Ideal for media with particulate matter (e.g., drilling mud).

PEEK: Compressive strength 120 MPa, temp range -60°C to 250°C, friction coefficient 0.15~0.25. Applied in high-pressure hydraulic systems (≤70 MPa).

Copper Alloy: Compressive strength 300 MPa, temp range -200°C to 400°C, friction coefficient 0.10~0.20. Used in ultra-high-pressure valves (>100 MPa).

Polyimide (PI): Compressive strength 150 MPa, temp range -269°C to 350°C, friction coefficient 0.20~0.30. Designed for extreme aerospace environments.

Nanocomposites: Compressive strength ~180 MPa* (Graphene-reinforced PEEK, 15% filler, 50% strength increase), temp range -50°C to 300°C, friction coefficient ~0.05~0.10 (60% reduction). Qualified for nuclear reactor primary loops (radiation-resistant).

Surface Functionalization:

Solid Lubrication Layers:

MoS₂ Sputter Coating (2~5μm): Reduces friction coefficient to 0.03 for oil-free environments.

DLC (Diamond-Like Carbon) Coating: Hardness HV 3000, increases service life 10x against particle erosion.

Anti-sticking Treatment: Nano-silica modification (contact angle >150°) prevents rubber adhesion to the ring.

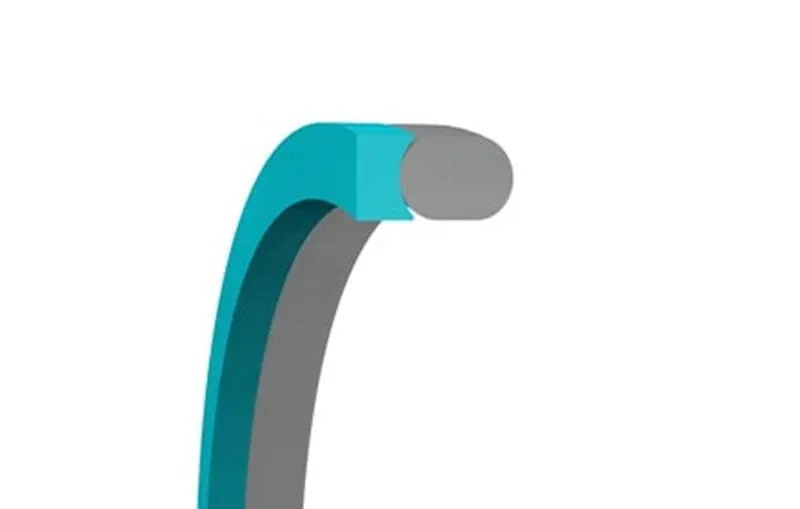

III. Structural Design: Geometry Enhancing Seal Reliability

Comparison of Classic Structural Types:

Straight-Wall Type: Rectangular cross-section. Pressure load: Unidirectional. Extrusion resistance: Moderate (≤40 MPa). Applications: Static O-ring seals.

Angled Type: Trapezoidal cross-section with angled face(s). Pressure load: Bidirectional. Extrusion resistance: High (≤100 MPa). Applications: Hydraulic cylinder reciprocating seals.

Stepped Type: Multi-stage ledge profile. Pressure load: Multidirectional. Extrusion resistance: Extreme (>150 MPa). Applications: Ultra-high-pressure valves.

Segmented Type: Split ring structure. Pressure load: Moderate-High (≤80 MPa). Applications: Large flange maintenance without disassembly.

IV. Industry Applications & Performance Breakthroughs

Ultra-High-Pressure Hydraulic Systems (Construction Machinery):

Challenge: 70 MPa continuous pressure, 0.1mm gap, contamination by hard particles.

Solution: Graphene-PEEK composite ring (180 MPa comp. strength) paired with U-shaped polyurethane seal + angled ring.

Result: Service life extended from 500 hours to 5000 hours.

Supercritical CO₂ Turbines (Power Equipment):

Challenge: 100 MPa / 200°C supercritical state, high CO₂ molecule permeability.

Solution: Stepped copper alloy ring (MoS₂ coated) supporting metallic C-seal.

Result: Leakage rate <1×10⁻⁶ mbar·L/s.

Aerospace Rocket Fuel Valves:

Challenge: LOX (-183°C) / LH2 (-253°C), vibration loads up to 20g.

Solution: Segmented polyimide ring (CTE matched to metal) supporting helium-filled metallic O-ring.

Validation: Passed NASA-STD-5012 cryogenic cycling tests.

V. Installation Procedures & Failure Prevention

Critical Installation Steps:

Gap Measurement: Verify 3D cavity dimensions/tolerances using air gauging (±0.001mm accuracy).

Surface Finishing: Achieve ring mounting surface roughness Ra≤0.4μm via diamond wheel polishing + electrolytic passivation.

Thermal Assembly: Cool ring with LN2 (-196°C) and press-fit (interference fit 0.02mm).

Stress Monitoring: Use foil strain gauges with wireless DAQ (e.g., HBM systems) to detect assembly stress.

Typical Failure Modes & Solutions:

Ring Fracture: Cause: Insufficient material toughness or impact loads. Solution: Switch to PI/PEEK composites.

Primary Seal Shear Damage: Cause: Sharp ring edge without chamfer (radius <0.1mm). Solution: Add R0.3mm radius + polishing.

Excessive Wear: Cause: Frictional heat buildup leading to thermal expansion seizure. Solution: Add cooling grooves + nano-lubrication coating.

VI. Technology Frontiers: Smart & Sustainable Innovations

Function-Integrated Rings:

Embedded sensors (e.g., TE Connectivity MS series piezofilm) for real-time contact pressure monitoring.

Self-adjusting structures with SMA (Shape Memory Alloy) for temperature-compensated gap control.

Additive Manufacturing Breakthroughs:

Topology-optimized lattice structures (40% weight reduction, stiffness maintained).

Gradient material printing: High hardness (ceramic) at contact zone, high toughness (polymer) at support zone.

Green Circular Technologies:

Bio-based polymers (e.g., Castor oil-derived PEEK – Covestro APEC® series).

Chemical depolymerization recycling using supercritical CO₂: Monomer recovery rate >95% for PEEK rings.

Conclusion: The “Invisible Guardian” of High-Pressure Sealing

The value of the anti-extrusion ring lies in its mechanical re-engineering capability – transforming vulnerable polymer seals into rigid fortresses capable of withstanding hundreds of megapascals.

Post time: Jun-09-2025