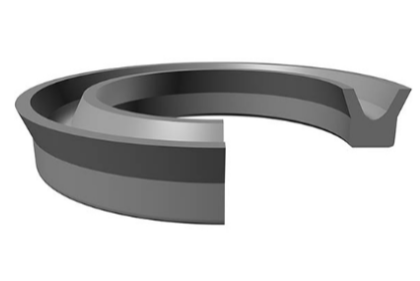

The performance of seals directly determines the reliability, efficiency, and lifespan of hydraulic and pneumatic systems. Traditional seal designs are often tailored for a single sealing scenario: either for the piston (bore seal) or the piston rod (rod seal). This necessitates engineers to select, stock, and manage two different seal types for different installation locations. The Bore/Piston Rod Dual-Purpose Y-Ring, depicted in the image, is an innovative design born to eliminate this complexity. Leveraging its unique one-piece structure, it enables a single part to adapt to two sealing conditions, making it an ideal choice for the design of modern, compact, highly reliable, and easily maintainable equipment.

1. Core Design Analysis: One “Y”, Multiple Uses – Ingenuity Over Brute Force

1.1 Structural Essence: The Wisdom of the Asymmetrical “Y”

The core of the dual-purpose Y-ring lies in its meticulously designed cross-section. Unlike symmetrical U-rings, its primary and secondary sealing lips typically feature differentiated designs in length and angle. This seemingly subtle asymmetry is the physical basis for its dual-purpose capability. The long, flexible primary lip provides the main sealing force under pressure, while the shorter, more supportive secondary lip provides auxiliary sealing at low pressure or vacuum and wipes away excess media during the dynamic stroke.

1.2 Self-Sealing and Adaptive Principle

Unlike common O-rings, which rely on pre-compression, the Y-ring employs a pressure-activated self-sealing mechanism. When system pressure (P) is applied, the medium pressure forces the root of the primary lip to expand outward (for bore seal) or inward (for rod seal), precisely conforming to the sealing groove wall or piston rod surface, forming a dynamic seal. Higher pressure results in stronger contact force, achieving excellent zero or minimal leakage sealing. When pressure decreases, the Y-ring’s own elasticity allows it to recover, preventing excessive friction and wear.

1.3 Dynamic Lubrication and Wiping Function

The lip edges of the Y-ring are typically designed with minute radii or chamfers. In rod seal mode, this helps form and maintain an extremely thin lubricating film, significantly reducing startup and running friction. In bore seal mode, it also aids lubrication. The clever angle of its secondary lip effectively scrapes back contaminants or excess fluid adhering to the piston rod, combining dust protection and wiping functions.

2. Core Advantages: Four Values Beyond Traditional Seals

2.1 Universal Interchangeability, Simplifying Inventory and Maintenance

This is its most significant advantage. One part, two applications greatly simplifies design selection, spare parts management, and on-site maintenance procedures, reduces downtime risks caused by incorrect part numbers, and significantly lowers overall procurement and management costs.

2.2 Wide Pressure and Speed Range, Excellent Performance

Thanks to its pressure-energized sealing principle, the dual-purpose Y-ring maintains stable sealing over a wide pressure range from vacuum to medium/high pressure (typically up to 40MPa or even higher). Its low-friction, anti-extrusion design also makes it suitable for a wide speed range with responsive dynamic performance.

2.3 Low Friction and Long Service Life

The unique lip design and the use of high-quality materials (such as Polyurethane PU, Hydrogenated Nitrile Butadiene Rubber HNBR) ensure low breakaway torque and a stable running friction coefficient, reducing system energy consumption and heat generation. Good wear and extrusion resistance, combined with the self-cleaning effect of its wiping function, collectively ensure a longer operating life.

2.4 Easy Installation and High Reliability

The one-piece structure eliminates potential misalignment issues that can occur with multi-piece seal sets. Its groove design is typically a standard rectangular groove, making installation straightforward and offering relatively high tolerance for groove machining, reducing the risk of early failure due to improper installation.

3. Material Science and Application Scenarios

3.1 Key Material Selection

Material determines performance boundaries. Common choices include:

- Polyurethane (PU, e.g., AU/EU): Excellent wear and extrusion resistance, high load-bearing capacity, the preferred choice for high-pressure, heavy-duty conditions, widely used in construction machinery hydraulic cylinders.

- Nitrile Rubber (NBR): High cost-effectiveness, good oil resistance, suitable for general hydraulic oils and a wide range of industrial applications at medium pressures.

- Hydrogenated Nitrile Rubber (HNBR): Significantly improved heat, oil, and chemical resistance over standard NBR, suitable for harsher environments.

- Fluorocarbon Rubber (FKM): Excellent high-temperature and chemical corrosion resistance, used in high-temperature fuel, special hydraulic fluids, and corrosive media environments.

3.2 Typical Application Areas

- Mobile Hydraulic Systems: Bucket and arm cylinders for excavators, loaders, requiring high pressure resistance, impact resistance, and long life.

- Industrial Automation Equipment: Clamping, ejection cylinders for injection molding machines, machine tools, emphasizing high response, low friction, and compact design.

- General Pneumatic Systems: Piston and piston rod seals for air cylinders, requiring low friction, fast response, and long life.

- Auxiliary Function Units: Medium/low-pressure systems in agricultural machinery, material handling equipment, valuing its versatility and reliability.

4. Selection, Installation, and Precautions

4.1 Key Points for Correct Selection

- Condition Analysis: Clearly defining working pressure, speed, temperature, and media is the foundation for selection. PU is preferred for high pressure/speed; FKM/HNBR for high temperature/chemical resistance.

- Dimensional Matching: Precisely measure and match groove dimensions, shaft/bore diameters, and fit tolerances. Excessive clearance leads to extrusion failure; insufficient clearance causes high friction and installation difficulty.

- Orientation Confirmation: During installation, the primary sealing lip must face the medium side to be sealed (i.e., the pressure side). This is key to its self-sealing function.

4.2 Installation and Maintenance Specifications

- Installation Tools: Must use dedicated installation sleeves or taper tools to avoid cutting or nicking the sealing lips on sharp threads or steps during installation.

- Groove Cleanliness: Ensure the groove is free of burrs, metal chips, and contaminants. Deburr and polish if necessary.

- Lubrication: Apply system-compatible grease or the working medium to the seal and sliding surfaces before installation to protect the seal and reduce startup friction.

5. Summary and Outlook

The Bore/Piston Rod Dual-Purpose Y-Ring, with its philosophy of “One ‘Y’, Multiple Functions – Ingenious Design”, perfectly balances sealing performance, versatility, and economy. It is not merely a component solving a single sealing challenge but embodies an engineering philosophy that promotes modular system design and simplified maintenance.

Post time: Jan-09-2026