Core Functions & Operational Challenges

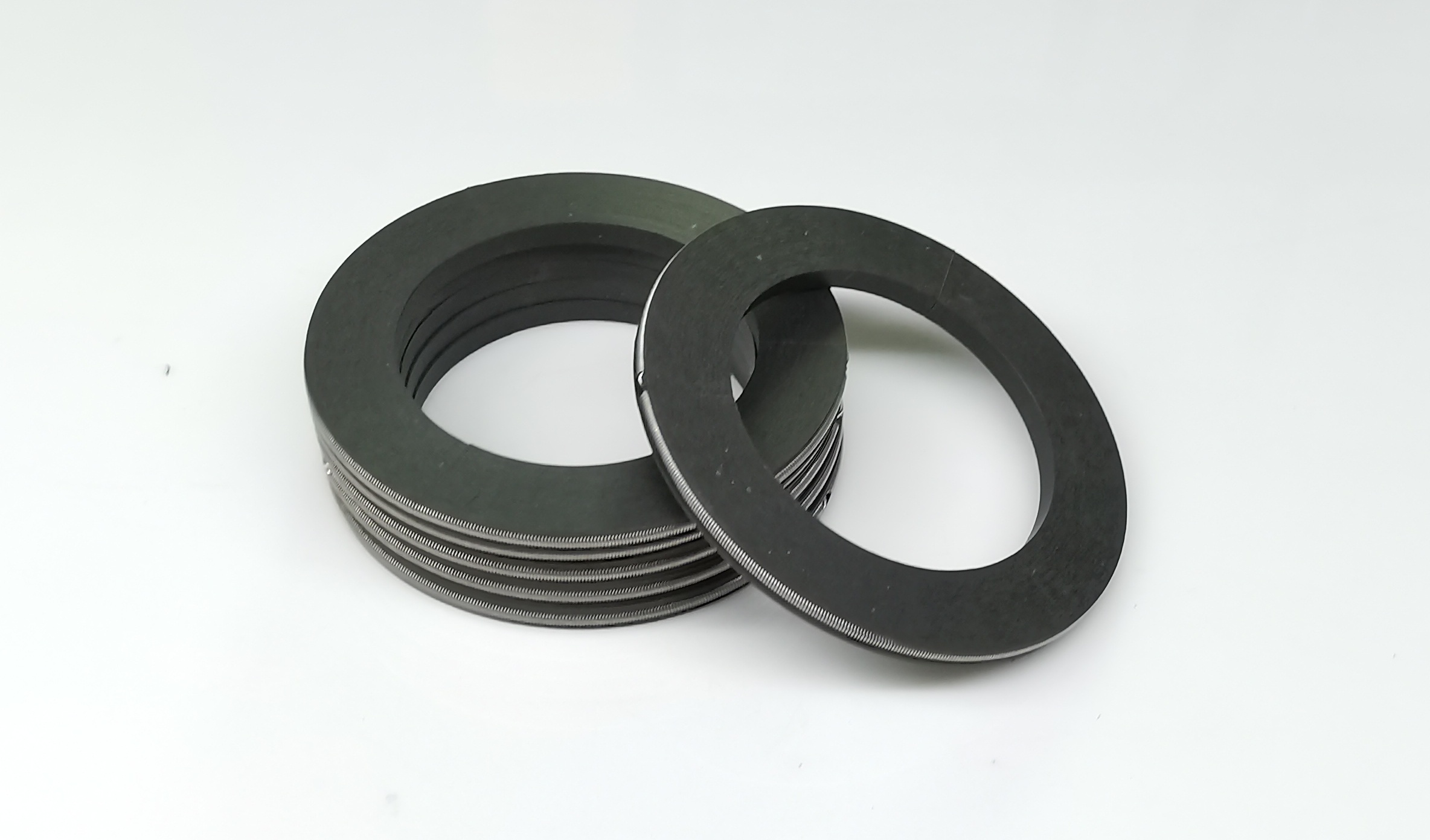

Oil Control Rings act as the “blood purifier” in reciprocating compressors, performing two critical tasks:

- Oil Scraping Precision: Removes excess oil (film ≤3μm) from cylinder walls during piston downstroke to prevent contamination (ISO 8573-1 oil content ≤0.1mg/m³).

- Sealing Control: Retains 0.8-1.5μm oil film during upstroke, reducing friction power loss by 15-20%.

Extreme Condition Challenges:

- Axial vibration (>500N side force)

- Thermal degradation (180–220°C in Stage 2)

- Acidic emulsion corrosion (oil + condensate)

Material Revolution: Nano-PTFE Composite

| Property | Cast Iron + Chrome | Nano-PTFE Composite | Improvement |

|---|---|---|---|

| Friction Coefficient | 0.12–0.18 | 0.04–0.07 | ↓65% |

| Oil Film Control | ±2.5μm | ±0.8μm | ↑72% |

| Max. Temperature | 150°C (coating failure) | 260°C | ↑73% |

| Side Force Resistance | Requires >1.5mm thickness | 0.8mm thin-wall design | Weight ↓40% |

Material Innovations:

- Base: PTFE + 25% carbon fiber (modulus ↑ to 5.2 GPa)

- Lubrication: MoS₂ nanosheets (80nm)

- Anti-corrosion: FFKM edge coating (pH 2–12 resistant)

Structural Optimization: Dual-Gradient Edge Tech

- Asymmetric Dual-Edges:

- Upper edge: 5° negative rake, 0.3MPa contact pressure → efficient scraping

- Lower edge: 12° positive rake, 0.08MPa → uniform oil distribution

- Drainage Channels:

- Laser-etched micro-holes (Φ0.3mm×120) → 3× faster drainage

- R=0.05mm curved grooves (EDM machined) → prevent oil retention

Performance Data (55kW Screw Compressor)

| Parameter | Traditional Ring | Nano-PTFE Ring | Benefit |

|---|---|---|---|

| Oil Consumption | 18g/h | 5g/h | Saves ¥67k/year* |

| Friction Power Loss | 8.2kW | 6.5kW | ↓21% energy |

| Oil Carryover | 0.8mg/m³ | 0.06mg/m³ | Class 0 compliant |

| Maintenance Interval | 4,000h | 12,000h | ↓65% labor cost |

8,000h/year operation; electricity ¥0.8/kWh; lubricant ¥150/kg

Industry Applications

- Oil-Free Compressors: Achieves Class 0 without oil separators (-30% weight).

Case: Medical O₂ generator oil content: 0.5ppm → 0.01ppm. - 35MPa H₂ Compressors: 5,000h test passed (no hydrogen embrittlement).

- High-Speed VFD Compressors: Supports >6m/s piston speed (vs. 4m/s limit).

Maintenance Guidelines

Failure Thresholds:

| Parameter | Normal Range | Replacement Limit | Inspection Method |

|---|---|---|---|

| Radial Clearance | 0.1–0.3mm | >0.6mm | Feeler gauge |

| Face Warping | ≤0.02mm | >0.1mm | Optical flat |

| Edge Radius (Ra) | 0.2μm | >1.6μm | Profilometer |

Installation:

- Cryogenic assembly (-40°C with LN₂)

- 120°±5′ seam alignment (laser alignment)

Next-Gen Tech:

- Smart rings with piezoelectric sensors (±0.1μm oil film monitoring)

- Self-healing coatings (fluorinated lubricant microcapsules)

Post time: Jul-17-2025