A compressor, serving as the “heart” that provides power and air in the industrial sector, has its core efficiency and reliability largely dependent on a small yet critical component—the compressor valve. Known as the “heart valve” of the compressor, it precisely controls the process of gas intake, compression, and discharge. Its performance directly determines the compressor’s efficiency, energy consumption, and service life.

1. What is a Compressor Valve?

A compressor valve is an automatic valve, a type of check valve, installed on the compressor cylinder. It requires no mechanical drive; instead, it opens and closes automatically based on the pressure difference between the cylinder and the external pipeline (or intake/exhaust chambers). Its basic working cycle is as follows:

- Intake Process:When the piston moves, causing the cylinder pressure to fall below the intake pipe pressure, the intake valve plate opens under the pressure difference, overcoming spring force and inertia. Gas is sucked into the cylinder. The exhaust valve remains closed.

- Compression and Exhaust Process:When the piston moves in the opposite direction, compressing the gas and raising the cylinder pressure above the exhaust pipe pressure, the exhaust valve plate opens under the pressure difference. The compressed gas is discharged. The intake valve remains closed.

Through this rapid, repeated opening and closing, the valve ensures the gas flows in a single direction, completing the compressor’s work cycle.

2. Core Functions and Operating Requirements: A Precise Dance in Harsh Conditions

The operating conditions of a valve are extremely severe. It must open and close reliably hundreds to thousands of times per minute under high temperatures, pressure differentials, and high frequency. Its core requirements can be summarized as:

- Good Sealing:It must close quickly and tightly. Any leakage directly reduces the compressor’s volumetric efficiency and increases energy consumption.

- Timely Opening/Closing, Low Resistance:The valve plate should open promptly when the pressure difference forms and seat quickly when closure is needed. The flow resistance as gas passes through the valve must be low to minimize energy loss.

- Long Service Life and Durability:The valve plates and springs endure repeated impacts and alternating stresses thousands of times per minute, requiring high fatigue strength and wear resistance.

- Small Clearance Volume:The space in the valve passage and behind the valve plate creates “clearance volume.” High-pressure gas remains in this space at the end of the exhaust stroke, which expands during the intake stroke, reducing the actual amount of gas drawn in. Excellent valve design minimizes this clearance volume.

3. Typical Structure and Key Components

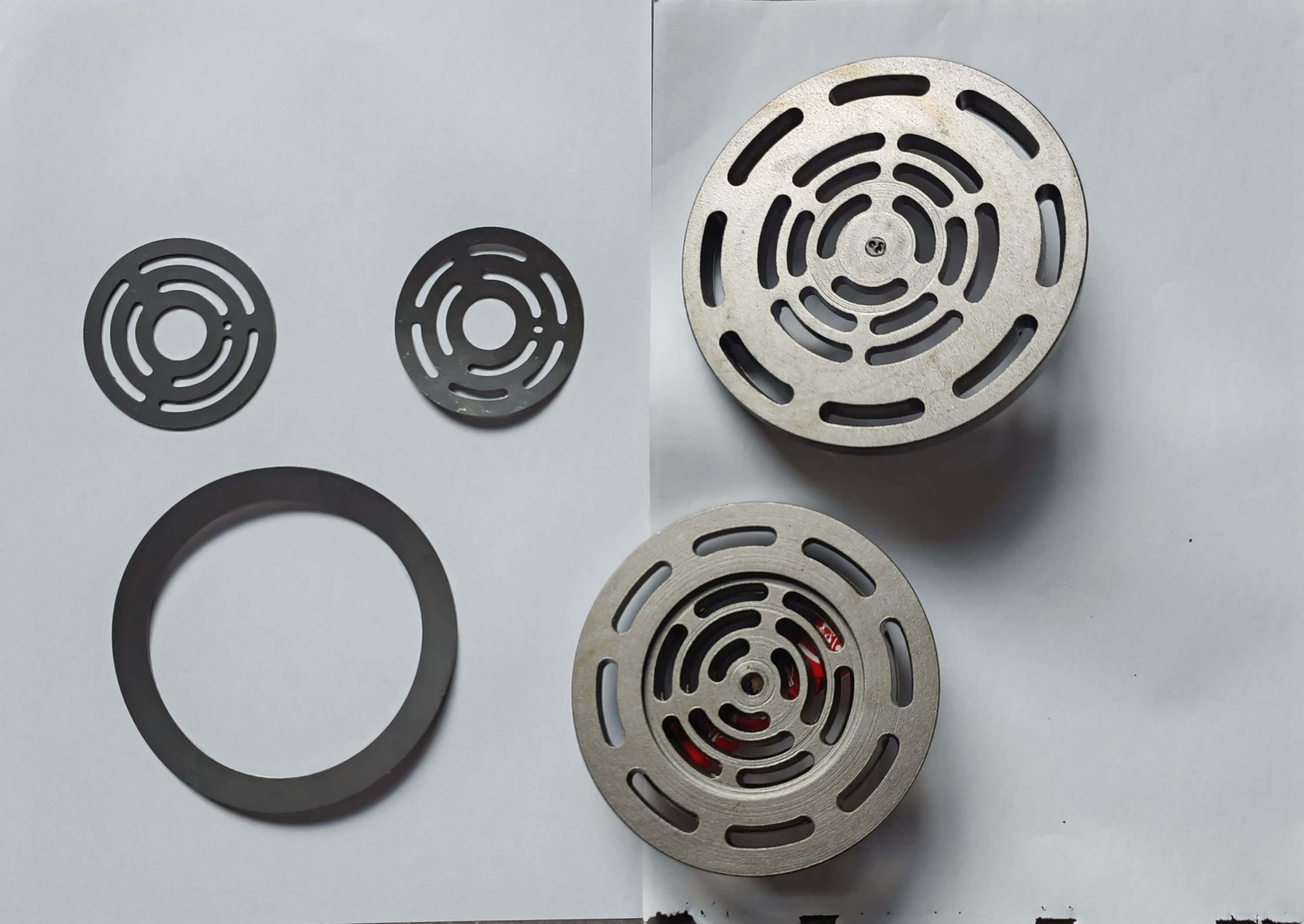

A complete compressor valve typically consists of the following components:

- Valve Seat:The base part of the valve, featuring gas flow channels. The valve plate seals against it. The flatness of its sealing surface is critical.

- Valve Plate:The core moving part responsible for opening and closing the flow channel. Traditional plates are ring-shaped or strip-shaped; modern high-performance plates can also be mesh-type (channel valves). Materials commonly include alloy steel, stainless steel, PEEK (polyetheretherketone), and other engineering plastics or composites.

- Spring:Provides the force to close the valve plate and cushions the impact when it opens. Its stiffness and pre-tension directly affect the valve’s opening/closing characteristics.

- Lift Limiter:Restricts the maximum opening height (lift) of the valve plate and acts as a support for the spring. Its structure also influences the smoothness of gas flow.

These components are assembled into a complete valve unit via bolts or connectors for easy installation and maintenance.

4. Main Types and Evolution

Based on the movement and structure of the valve plate, compressor valves are mainly divided into:

- Ring Plate Valve:The longest-standing and most widely used type. The valve plates are ring-shaped; multiple rings can be arranged coaxially. They are rigid and suitable for high-pressure applications. However, they are relatively heavy, have high inertia, and limit rotational speed.

- Mesh Plate Valve:The valve plate is mesh-like, connecting multiple ring segments. It moves with uniform force, is less prone to jamming, and opens/closes more smoothly, making it suitable for high-speed compressors. However, its structure is complex and manufacturing is difficult.

- Reed Valve (or Flapper Valve):The valve plate is disc-shaped, using its elastic deformation to open and close. It has a simple structure and small clearance volume, often used in small, micro-compressors (e.g., refrigerator compressors). But its flow capacity and pressure tolerance are limited.

- Poppet Valve (or Channel Valve):A mainstream choice for modern high-efficiency compressors. The valve plate is often a strip or tongue-shaped thin piece made of plastic (like PEEK). It is lightweight, opens/closes rapidly, has low flow resistance, and is highly efficient. Widely used in the intake valves (unloading valves) of screw and scroll compressors.

Valve technology is evolving towards lightweight, low flow resistance, and long life. The application of new materials (e.g., composites) and processes (e.g., precision stamping, coating technology) is key to this progress.

5. Importance: A Small Plate, a Major Impact

The valve is one of the most vulnerable components in a compressor. Its condition directly determines the operating economy and reliability of the entire machine.

- Master of Energy Efficiency:Valve resistance loss and leakage are primary sources of energy loss in compressors. A set of efficient, well-sealed valves can significantly reduce electricity consumption per unit of air output.

- The “Weak Link” in Reliability:Fatigue fracture of valve plates or springs is a common compressor failure, which can lead to severe accidents like “piston impact” if it occurs, causing complete shutdown or damage.

- Key Cost Factor:Regular maintenance and replacement of valves are significant expenses in compressor upkeep. Long-lasting valves effectively reduce maintenance costs and downtime.

Conclusion

The compressor valve, a precision component dancing thousands of times per minute within a confined space, embodies the technical sophistication of the compressor. From traditional metal ring valves to modern plastic channel valves, each evolution brings improvements in compressor efficiency, reliability, and noise levels. For compressor designers, users, and maintenance personnel, a deep understanding and correct selection/maintenance of this “heart valve” is the foundation for ensuring the efficient, long-lasting, and stable operation of this power core.

Post time: Nov-13-2025