The D-type sealing ring, as the name suggests, is a sealing ring with a D-shaped cross-section. Essentially, it can be understood as a variant of the O-ring with a square base. This special structure provides a larger base contact area compared to ordinary O-rings, effectively eliminating the possibility of twisting and spiral failure, and demonstrating excellent sealing performance under high pressure and harsh conditions

.

Compared to ordinary O-rings, the D-type sealing ring has stronger shear resistance and significantly reduces damage caused by twisting during sealing operations. This makes it provide more reliable sealing effects in reciprocating motion (dynamic sealing), such as piston rod sealing in hydraulic and pneumatic systems, and other working environments where O-ring performance is unsatisfactory

.

01 Structural Features and Working Principle

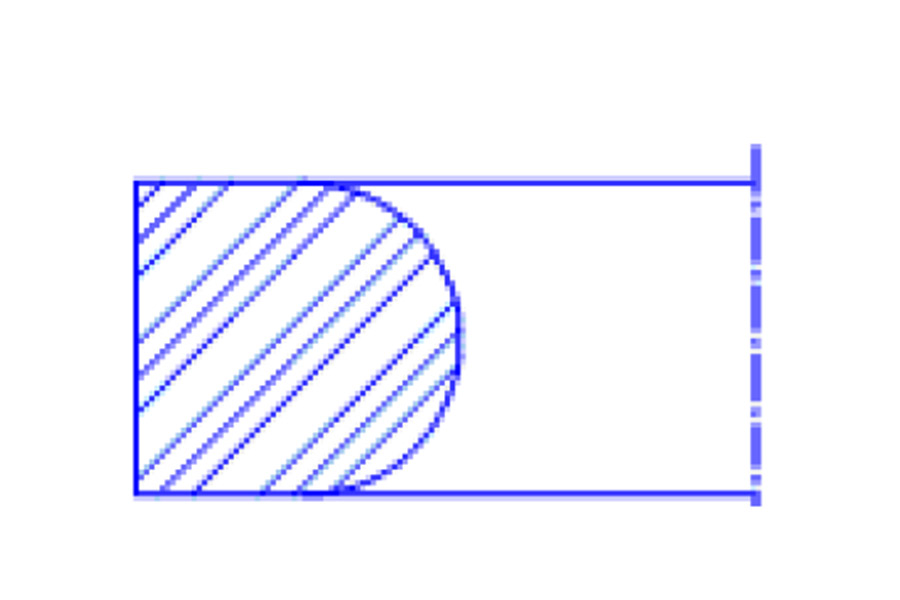

The structural design of the D-type sealing ring cleverly combines the simplicity of the O-ring with the reliability of specialized sealing rings. Its uniqueness lies in the combination of a rectangular base and an arc-shaped top. This design retains the elastic sealing characteristics of the O-ring while improving anti-twisting ability by increasing the base contact area

.

In terms of sealing mechanism, the D-type sealing ring is a typical extrusion-type sealing element. During use, it generates initial contact stress through pre-compression. When the system pressure increases, the sealing ring is further pushed against the sealing surface, enhancing the sealing effect

.

The sealing performance of the D-type sealing ring mainly depends on three key parameters: pre-compression rate, medium pressure, and structural parameters. The pre-compression rate is the initial compression amount during installation, usually controlled at about 10%. The structural parameters refer to the ratio of the rectangular height of the base to the arc height of the cross-section, which directly affects the overall performance of the sealing ring

. Under high-pressure conditions, the cross-sectional deformation of the D-type sealing ring is significant. To adapt to high-pressure environments, it is usually necessary to use a retaining ring to prevent extrusion damage .

02 Types and Application Fields

D-type sealing rings are mainly divided into two categories: Solid D-type sealing rings and Inflatable D-type sealing rings, which are suitable for different industrial scenarios

.

Solid D-type sealing rings are usually made of rubber material and are suitable for conventional hydraulic and pneumatic systems. For example, the D-shaped sealing ring used in seawater butterfly valves of nuclear power units is a typical solid structure

.

Inflatable D-type sealing rings have a hollow structure and can be controlled via an air valve for inflation and deflation

. This controllable sealing characteristic gives inflatable D-type sealing rings unique value in the following areas:

- Large hatches and ports: Used for sealing gap changes caused by machining precision, assembly precision, or thermal expansion and contraction

.

- Automatic bag filling for powdered foods: Improve filling efficiency

.

- Frequently opened and closed pipeline ports and valves: Especially suitable for dust pipelines in the power and chemical industries, significantly reducing maintenance time and installation difficulty

.

03 Material Selection and Performance Optimization

The material selection for D-type sealing rings is crucial for their sealing performance and service life. According to different working conditions, engineers choose different rubber materials to meet specific needs

.

Taking the D-shaped sealing ring for seawater butterfly valves in nuclear power units as an example, considering harsh conditions such as seawater corrosion, particle冲刷, and fatigue stress, Hydrogenated Nitrile Butadiene Rubber (HNBR) becomes the preferred material. HNBR has excellent mechanical properties, good chemical stability, good oil resistance and aging resistance, and excellent high and low-temperature performance

.

To improve the tear resistance of the sealing ring and prevent large tearing and breakage, modern D-type sealing rings usually incorporate skeleton materials internally. Commonly, nylon fiber is used as the skeleton material because of its high breaking strength, good fatigue resistance, good elasticity, and good wear resistance

. The selection of adhesive is also crucial .

The manufacturing process of D-type sealing rings is also very particular. Each step requires precise control

.

04 Installation and Maintenance Points

Correct installation and maintenance are key to ensuring the optimal performance of D-type sealing rings. Statistics show that about 60% of early failures of sealing rings are due to improper installation

.

When installing D-type sealing rings, the following professional specifications should be followed:

- Special Tool Installation: Use sleeve tools to prevent damaging the sealing ring

.

- Surface Treatment: The surface roughness of the shaft should be controlled at Ra 0.2-0.8 μm

.

- Standardized Lubrication: Apply lubricant of the same system during installation

.

- Direction Confirmation: Pay attention to the direction marks on the sealing ring

.

In terms of maintenance, it is recommended to regularly check the status of the sealing ring. Regular pressure tests help detect potential problems and avoid system failures

.

05 Technological Development and Prospects

With the advancement of materials science and engineering technology, technological innovation of D-type sealing rings is continuously advancing. The development of tear-resistant seawater butterfly valve D-shaped sealing rings represents the latest development direction in this field

. Through optimized product structure and improved manufacturing processes, the tear resistance and sealing performance of the new generation of D-type sealing rings have been significantly improved, with a service life of up to 10 years, meeting the requirements for use under extreme conditions .

As industrial equipment develops towards high pressure, high temperature, and high speed, higher requirements are placed on sealing technology. As a mature and reliable sealing solution, the D-type sealing ring will continue to play a key role in various industrial fields, and its technology will continue to innovate and improve with the progress of materials science and manufacturing technology

.

Post time: Oct-22-2025