In extreme conditions involving high temperatures, high pressures, and strong corrosion, traditional elastomeric seals often fall short. Metallic seals excel as critical “safety valves” for key equipment. Among them, the Internal Pressure-Activated Metallic E-Seal stands out for its unique structure and performance. This article delves into its structural features, working principles, material choices, and applications.

1. Structural Uniqueness: The Design of the E-Seal

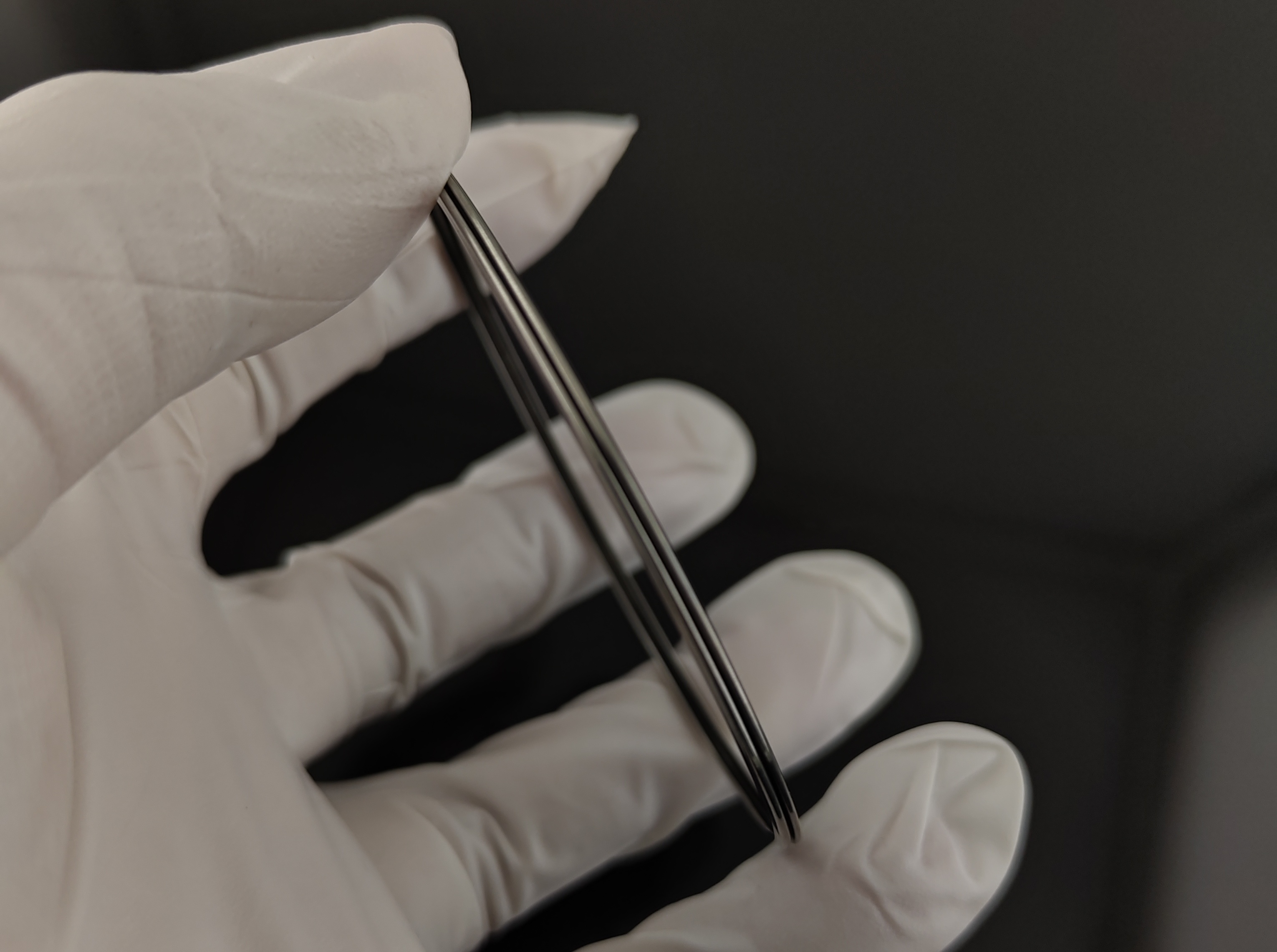

The E-Seal features a distinctive mirror-symmetrical “E” or “M” cross-section (typically with three peaks). Key structural elements include:

- ”M” Profile: A central groove forms a natural sealing chamber, while dual symmetric peaks serve as primary sealing lips. This groove is critical for self-activation.

- Support Structure: Used with concentric inner support rings (or outer constraint rings) to prevent extrusion and channel pressure toward sealing lips.

- Metal Core: Made from deformable metal alloys for plasticity.

Structural Differences vs. Other Metallic Seals:

| Comparison | Key Distinctions |

|---|---|

| Solid/Hollow Metal O-Rings | E-Seal’s groove amplifies pressure-to-radial-sealing-force conversion efficiency. |

| C-Seals | Dual lips and sealed chamber enable faster/stronger pressure-responsive sealing. |

| Delta Rings | More robust against gap changes; higher efficiency in pressure utilization. |

2. Core Mechanism: Pressure-Activation Principle

The E-Seal’s superiority lies in its pressure self-energization:

- Preload: Initial bolt tightening plastically deforms lips for primary sealing.

- Pressure Intrusion: System pressure enters the central chamber.

- Force Transformation: Pressure acts on chamber walls, forcing lips radially outward/inward. Support rings confine displacement, converting pressure into sealing force against flange surfaces.

- Bidirectional Sealing: Sealing pressure increases proportionally with system pressure (“tighter under pressure”).

3. Performance Advantages

- High-pressure reliability (up to 1,000+ MPa).

- Extreme temperature resilience (-196°C to 800°C).

- Superior corrosion/chemical resistance.

- Anti-extrusion (with support rings).

- Long service life, reusable (if undamaged).

4. Materials & Properties

| Material Category | Examples | Pros | Cons | Max Temp (°C) |

|---|---|---|---|---|

| Austenitic Stainless Steel | 304, 316L | Cost-effective, corrosion resistance | Low strength, SCC susceptibility | 600 (long-term) |

| PH Stainless Steel | 17-4PH (630) | High strength, corrosion resistance | Higher cost than austenitic steels | 400 |

| Ni-based Superalloys | Inconel 718/X-750 | High-temp strength, oxidation resistance | Expensive | 800 |

| Ni-based Corrosion Alloys | Hastelloy C-276 | Exceptional acid/halogen resistance | Very high cost | 400 |

| Special Alloys/Pure Metals | Ti Gr.2, Incoloy 925 | Targeted performance (e.g., Ti: lightweight) | Hydrogen embrittlement risk (Ti) | Varies |

Support rings use high-strength materials (e.g., hardened steel).

5. Applications

E-Seals are indispensable in:

- Oil & Gas: Wellheads (API 6A), Xmas trees, HPHT valves.

- Petrochemicals: Hydrocracking reactors, polyethylene units.

- Chemical Processing: Supercritical reactors, corrosive media.

- Nuclear: Reactor vessel closures, primary coolant loops.

- Aerospace: Rocket engine systems, test rigs.

- High-Pressure Research: Autoclaves, material synthesis chambers.

Post time: Jul-24-2025