Across petroleum extraction, transportation, and refining, sealing rings confront life-threatening challenges: H₂S corrosion, 140MPa ultra-high pressure, 450°C+ temperatures, and abrasive sand-laden crude oil. Failure may trigger blowouts, explosions, or environmental disasters. This article analyzes breakthrough paths through four dimensions: materials, structural design, field applications, and intelligent monitoring.

1. Hellish Challenges: Seals vs. Extreme Environments

- Crushing Pressure: >140MPa wellhead pressure (equivalent to 14,000m water depth)

- Scorching Heat: >200°C in geothermal wells / >450°C in cracking furnaces

- Toxic Corrosion: 20% H₂S concentration + 10MPa CO₂ partial pressure

- Abrasive Destruction: Quartz sand (Mohs 7 hardness) in 30% sand-content crude

- Fire Resistance: Must pass API 607 fire test (760°C/30min)

2. Material Breakthroughs: Ultimate Anti-Corrosion Armor

Polymer Systems

- FFKM: Withstands 327°C, resists H₂S corrosion (<0.5% swelling)

- FKM: Dominates 230°C operations at 65% lower cost than FFKM

- Glass-Filled PTFE: 80% lower wear rate vs pure PTFE, μ=0.05

- HNBR: Cost-efficient solution for <150°C environments

Metallic Defenders

- Hastelloy C276: Endures boiling sulfuric acid (<0.1mm/year corrosion)

- HVOF Coatings: Tungsten carbide sprays (1200HV) extend lifespan 8x

3. Structural Revolution: Active Defense Mechanisms

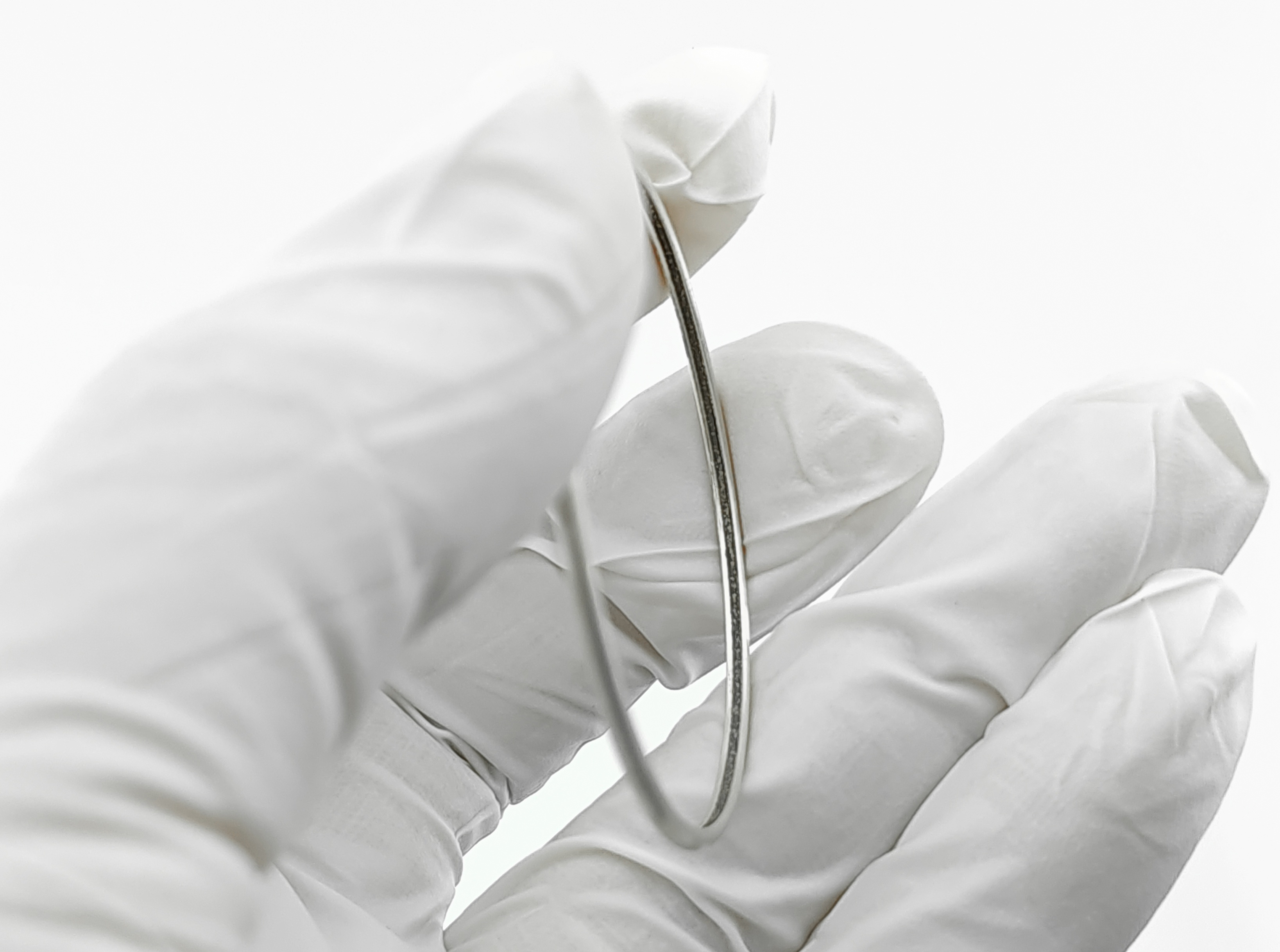

- Dual-Arch Metal C-Rings: Laser-welded design seals 250MPa (wellheads)

- Spring-Energized PTFE Seals: Multi-lip structure for ESP pumps (45MPa)

- Split Sand-Resistant Rings: Silicon carbide inserts combat particle erosion

- Fireproof Seals: Graphite-Inconel composites exceed API 607 standards

Safety Formula: Backup ring thickness = (Pressure × Gap)/(2 × Material Strength) + Abrasion Allowance (e.g., +0.5mm for sandy conditions).

4. Field-Proven Solutions

Case 1: 8,000m Ultra-Deep Wells (Iraq)

- FFKM O-ring + Inconel 718 metal ring

- Survived 175MPa/200°C/15% H₂S for 3+ years

Case 2: 30% Sand-Crude Transport (Canada)

- SiC-PTFE V-ring + split tungsten carbide ring

- Replacement cycle extended from 2 weeks to 6 months

Case 3: 450°C Catalytic Crackers (China)

- Laser-textured Haynes 230 C-ring

- Maintenance intervals increased from 1 to 4 years

5. Intelligent Monitoring: Digital Twin Defense

- Embedded MEMS sensors: Track contact pressure (±0.1MPa)

- Fiber Bragg Gratings: Detect abnormal strain in real-time

- RFID tags: Record thermal aging history for lifespan prediction

- Field data: Schlumberger’s SureTrack cut downtime by 70%

6. Next-Generation Technologies

- Nano-Enhanced Polymers: Graphene boosts thermal conductivity 3x

- Self-Healing Metals: Field’s Metal (m.p. 62°C) auto-seals cracks

- Bio-Based Elastomers: Dandelion rubber cuts carbon by 40%

The Triple Evolution

Sealing tech transforms through:

① Smart Materials: From corrosion resistance to H₂S adsorption

② Structural Power: Metal seals withstand 250MPa pressure

③ IoT Integration: Predictive maintenance via real-time data

With deep-earth drilling (>15,000m) and methane hydrate extraction advancing, quantum dot sensors and AI-driven material design will unlock Earth’s final energy frontiers.

Post time: Jun-12-2025