In industrial transmission and hydraulic systems, the reliability of sealing components directly determines equipment performance and service life. We introduce a sealing solution designed for harsh environments involving high pressure and high wear—the BA-Type High-Pressure Oil Seal with a built-in reinforcing O-ring. Its unique structural design and superior material properties ensure lasting sealing performance under extreme conditions.

1. Innovative Structure: Dual Sealing for Enhanced Reliability

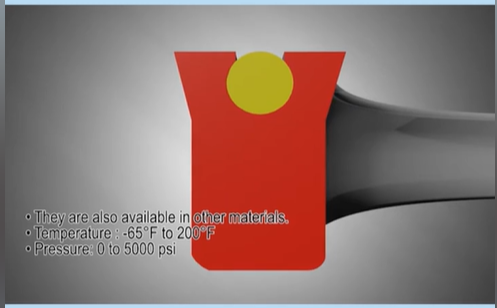

Unlike standard oil seals, this BA-type seal features an innovative composite design. A reinforcing O-ring is precisely embedded in a groove above the primary lip of the classic BA-type seal body.

- Primary Sealing Lip: Creates the dynamic sealing interface against the rotating shaft, effectively preventing media leakage.

- Built-in Reinforcing O-Ring: As the key feature, it provides a dual guarantee:

- Applies Constant Radial Force: It continuously exerts a steady tightening force on the seal body, compensating for normal lip wear and ensuring sealing stability throughout the seal’s service life.

- Enhances Static Sealing: Provides additional static sealing effectiveness when equipment is stopped or under low pressure, preventing seepage.

This dual mechanism of “dynamic lip sealing + static O-ring reinforcement” significantly improves sealing reliability and durability.

2. Key Performance Parameters: Wide Temperature Range and High-Pressure Tolerance

As indicated in the specifications, this seal boasts impressive performance metrics:

- Broad Temperature Range: Operates effectively within -65°F to +200°F. It maintains elasticity and sealing capability in both cold outdoor settings and high-temperature internal machine environments.

- High Pressure Resistance: Seals effectively across a pressure range from 0 to 5,000 PSI. This allows it to withstand pressure shocks and constant high pressure in most high-pressure hydraulic systems, heavy-duty pumps, and hydraulic cylinders, preventing seal extrusion or deformation.

3. Material Options: Tailored to Specific Needs

The note “They are also available in other materials” highlights its flexibility. Manufacturers can recommend the most suitable material (such as FKM, VMQ, or PTFE composites) based on your specific fluid media, operating temperature, and budget, ensuring an optimal match for your application.

4. Typical Applications

This high-performance BA-type oil seal is ideal for:

- Construction Machinery: Hydraulic cylinders and pump shaft seals in excavators, loaders, cranes, etc.

- Heavy-Duty Transmission Equipment: Gearboxes, transmission shafts.

- Industrial Pumps & Valves: Shaft seals for high-pressure centrifugal pumps, piston pumps.

- Automotive & Transportation: Powertrain systems in special vehicles.

Conclusion

In summary, the BA-Type Oil Seal with its built-in reinforcing O-ring offers powerful and reliable sealing protection for industrial equipment through its innovative dual-sealing structure, exceptional performance across wide temperature and pressure ranges, and flexible material options. Choosing this seal means opting for lasting safety and efficiency when facing the challenges of demanding operating conditions.

Post time: Oct-11-2025