In sealing and transfer systems handling highly corrosive media, extreme temperatures, and ultra-clean requirements, traditional materials often fall short. Polytetrafluoroethylene (PTFE) bellows, with their unique structure and material properties, have become critical components for solving such challenges. This article examines the design advantages of PTFE bellows, their core functions, and compares them with bellows made from alternative materials.

I. Structural Advantages & Core Functions

- Core Structure: Corrugated Design

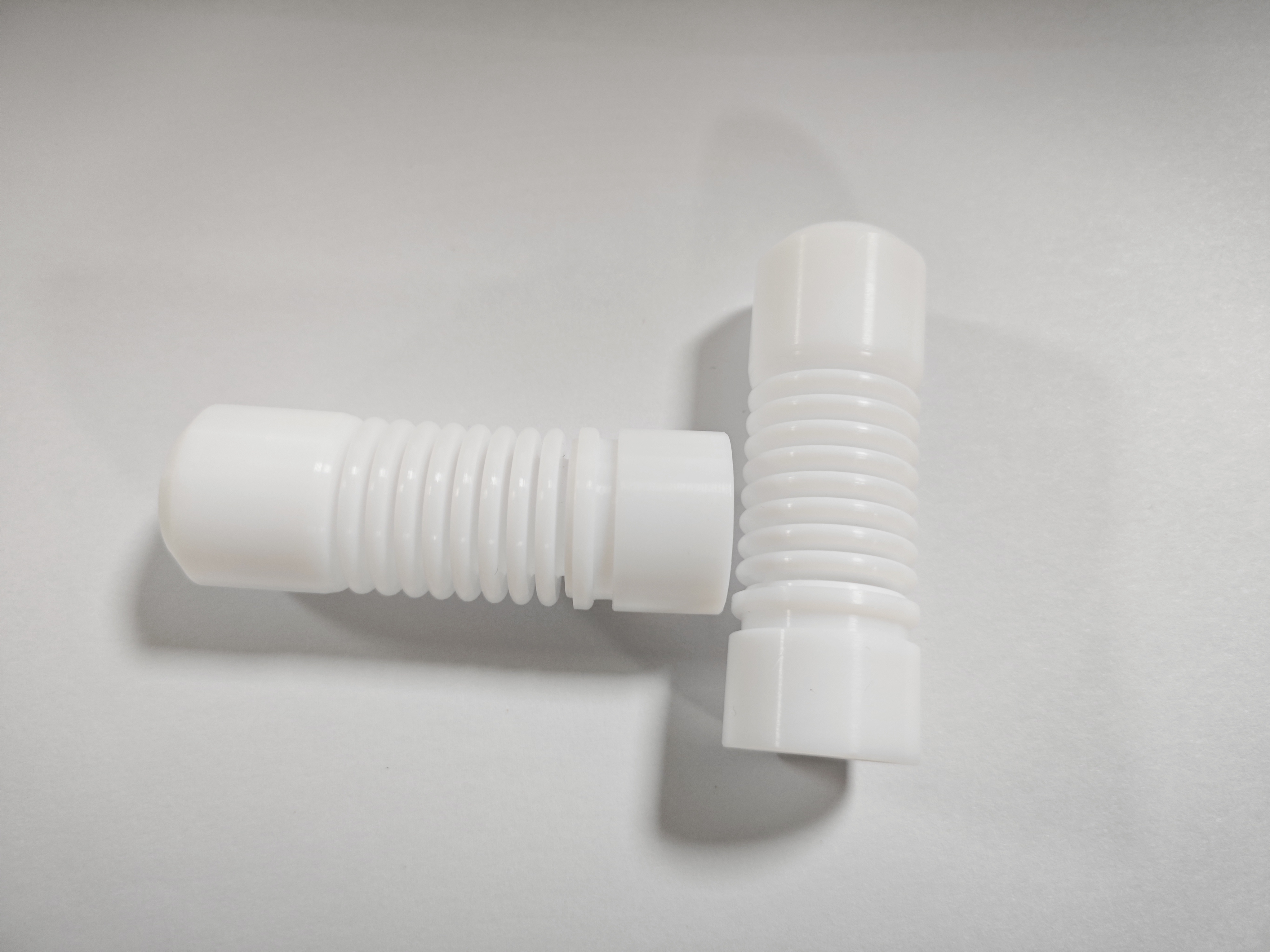

- Morphology: PTFE bellows are formed from homogeneous PTFE via processes like molding, welding, or winding, featuring continuous, uniform, flexible annular corrugations (U-shaped, V-shaped, or Ω-shaped).

- Key Component: The bellows themselves are the functional core, typically welded to flanges, fittings, or inserts for system integration.

- Design Benefits:

- Superior Axial/Radial Compensation: The corrugated structure provides exceptional flexibility and elasticity, enabling absorption of displacements caused by:

- Thermal expansion/contraction.

- Equipment vibration.

- Installation misalignment or foundation settlement.

- Vacuum Resistance & Stability: Corrugations enhance hoop stiffness, preventing collapse (under vacuum) or over-expansion (under pressure) better than smooth hoses.

- Long-Stroke Compensation: Single bellows units offer significant displacement compensation; multiple units can handle larger ranges.

- Uninterrupted Flow: Maintains seal integrity and media flow during compensation.

- Superior Axial/Radial Compensation: The corrugated structure provides exceptional flexibility and elasticity, enabling absorption of displacements caused by:

- Core Functions of Bellows:

- Displacement Compensation/Vibration Isolation: Primary purpose—absorbs stress to protect connected equipment (pumps, valves, reactors).

- Sealing & Isolation: Critical in mechanical seals (flexible connection for seal chambers) and valve stems (leak-free dynamic sealing), fully containing toxic/corrosive media.

- Media Transfer: Safely routes corrosive fluids in flexible piping systems.

- PTFE Material Advantages:

- Unrivaled Chemical Resistance: Inert to nearly all acids, alkalis, oxidizers, and solvents.

- Broad Temperature Range: Typically -70°C to +260°C (higher for short peaks).

- High Purity & Non-Stick: Smooth inner wall resists adhesion, ideal for pharma, food, and semiconductor applications.

- Electrical Insulation & Weather Resistance.

II. Bellows Function Summary

PTFE bellows combine corrugated flexibility (mechanical compensation) with PTFE inertness (environmental resistance) to solve rigidity and compatibility challenges.

III. Alternative Bellows Materials

| Material | Key Properties | Typical Applications |

|---|---|---|

| PTFE | Best chemical resistance; wide temp. range (-70–260°C); non-stick; low friction; lower pressure rating | Chemical pump seals; high-purity transfer; corrosive valves; pharma/food/semiconductor systems |

| Metal (316L, Hastelloy) | High pressure/heat resistance (500°C+); long fatigue life; rigid; costly; corrosion resistance varies | Steam pipelines; gas turbines; high-T valves; aerospace hydraulics/fuel lines |

| Rubber/Elastomer (EPDM, FKM) | High elasticity/damping; low cost; limited temp./chemical resistance; prone to aging | Automotive exhaust; HVAC ducts; cooling systems; low-pressure water/air lines |

IV. Key Applications of PTFE Bellows

- Chemical & Process Industries:

- Mechanical seals for pumps (containing toxic fluids).

- Bellows-sealed valves (zero-leak stem seals in chlorine/acid systems).

- Corrosive media transfer lines (reactors, tanks).

- Pharma & Biotech:

- Cleanroom piping connections.

- Bioreactor/lyophilizer sealing.

- Semiconductor & Electronics:

- Ultra-pure water (UPW)/chemicals (HF, ammonia) transfer.

- Etching/cleaning equipment connections.

- Food & Beverage:

- Hygienic fluid handling (dairy, bottling lines).

- Sticky media transfer (syrups, jams).

- Other:

- Lab equipment connections.

- Specialized sealing/vibration isolation.

Post time: Jul-28-2025