In power generation, chemical, marine, and coastal industrial facilities, the seawater makeup water system is a critical auxiliary system, responsible for supplying cooling medium to condensers, coolers, and other equipment. The interconnecting valve, as a key switching and control component of this system, has its sealing reliability directly related to the operational efficiency and safety of the system. The valve disc seal ring is the core component that ensures the interconnecting valve achieves its “zero leakage” shut-off function. This article delves into its function, performance, material, and installation.

1. Core Function and Importance

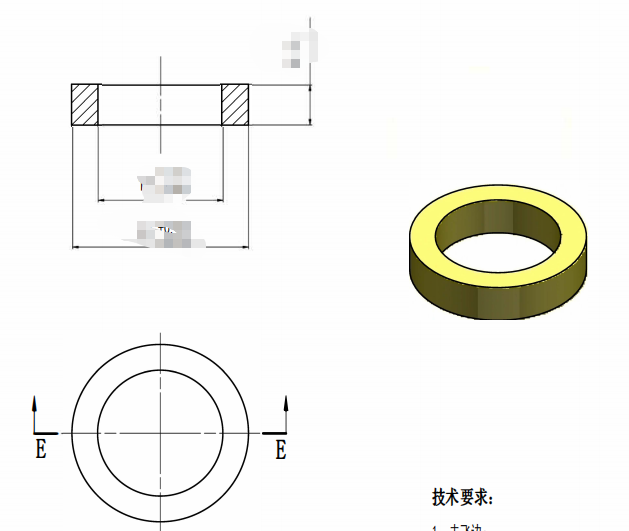

The valve disc seal ring is typically installed in the sealing groove of the valve disc. Its core function is: when the valve is closed, to elastically or plastically deform under the pressure of the valve stem, tightly fitting against the valve seat sealing surface, forming a physical barrier that completely blocks the flow of high-pressure, corrosive seawater.

Its importance is reflected in:

- Preventing Internal Leakage: Ensures the valve is tight and leak-free in the closed position, preventing cross-flow between systems, pressure loss, or accidental filling of standby equipment, guaranteeing the accuracy of system operational logic.

- Maintaining Efficiency: Minor leaks can lead to decreased system efficiency and energy waste. A tight seal is fundamental for economical system operation.

- Ensuring Safety: When isolation for maintenance is required, reliable sealing is a prerequisite for personnel and equipment safety.

- Resisting Harsh Conditions: As the first line of defense in direct contact with seawater, it must withstand long-term corrosion, erosion from silt, and system pressure fluctuations.

2. Key Performance Requirements

To fulfill the above functions, the valve disc seal ring must meet a series of stringent performance criteria:

- Excellent Corrosion Resistance: Must resist long-term corrosion and electrochemical erosion from seawater (containing high concentrations of chloride ions, microorganisms, etc.), with stable material properties, resisting pitting and crevice corrosion.

- Superior Elasticity and Resilience: During valve cycling, it must repeatedly compress and rebound, maintaining sufficient sealing specific pressure and compensating for minor deviations or wear between the valve disc and seat.

- Outstanding Wear and Erosion Resistance: Seawater often contains suspended solids (silt, shell fragments) which can erode sealing surfaces at high flow velocities. The seal material requires high hardness and toughness to resist this wear.

- Low Friction Coefficient and Self-Lubrication: Ensures smooth valve operation and stable torque, preventing “sticking” or seal damage due to excessive friction.

- Broad Temperature and Pressure Adaptability: Must operate stably within the common temperature range of seawater systems (typically -10°C to 50°C) and at system design pressures (usually from a few bar to several tens of bar) without significant performance degradation.

- Low Long-Term Compression Set: High recovery ability after prolonged compression, preventing seal failure due to permanent deformation.

3. Analysis of Common Materials

Material selection is fundamental to determining seal ring performance and lifespan. For seawater environments, common materials are:

- Nitrile Rubber :

- Advantages: Lower cost, good elasticity, wear resistance, and some oil resistance. Suitable for some low-pressure systems with good water quality and less extreme corrosion requirements.

- Disadvantages: Limited resistance to ozone and seawater corrosion (especially chloride ions). Prone to swelling, hardening, and cracking after long-term immersion, leading to relatively shorter service life. Not recommended for core, critical interconnecting valves.

- Ethylene Propylene Diene Monomer Rubber :

- Advantages: Excellent weather, ozone, and warm water (<100°C) resistance, and resistance to weak acids/bases. Performs better than NBR in seawater, with outstanding anti-aging properties and low compression set.

- Disadvantages: Poor resistance to hydrocarbon oils. A cost-effective and reliable choice for freshwater and seawater systems with good water quality.

- Fluoroelastomer :

- Advantages: Known as the “king of elastomers,” it has excellent high-temperature resistance (up to 200°C+), resistance to strong corrosive media (including concentrated acids, strong oxidizers), and superior aging resistance. Performs excellently in harsh seawater environments.

- Disadvantages: High cost, slightly lower elasticity at low temperatures. Suitable for critical main system interconnecting valves with extremely high reliability requirements and harsh conditions.

- Polytetrafluoroethylene :

- Advantages: Extreme chemical inertness, resistant to almost all chemical media, very low friction coefficient, excellent self-lubrication, wide operating temperature range.

- Disadvantages: Poor elasticity. Often used in combination with an elastomer (e.g., an O-ring) to form a “PTFE lip / elastomer backup” seal, or filled/modified PTFE is used to improve its cold flow properties. Commonly used for high-pressure, high-temperature, or applications with extreme chemical compatibility requirements.

- Specialty Engineering Plastics/Composites:

- Such as Ultra-High Molecular Weight Polyethylene, Polyphenylene, etc., offering high wear and corrosion resistance, and low friction, often used in specially designed seal rings.

Material Selection Advice: For typical seawater makeup system interconnecting valves, EPDM and FKM are mainstream and reliable choices. EPDM offers good cost-performance for most常规 conditions; FKM is for higher reliability applications. PTFE composites are often used for high pressure or as a supplement to hard seals.

4. Installation, Maintenance, and Technical Points

Correct installation is the final, yet most critical, step for the seal ring to perform.

- Pre-Installation Inspection:

- Cleaning: Thoroughly clean the valve disc groove, valve seat sealing surface, and the new seal ring, ensuring no debris, metal shavings, sand, or other foreign particles.

- Inspection: Verify the seal ring model and material conform to design requirements; check the seal ring for scratches, cracks, bubbles, flashes, etc.; measure key dimensions like cross-section diameter and inner diameter.

- Lubrication: Apply a lubricant compatible with both the seal material and seawater (e.g., silicone-based grease, perfluorinated polyether grease) to the seal ring and installation groove to reduce installation friction and prevent twisting.

- Installation Process:

- Avoid Sharp Tools: Use blunt plastic or copper tools, or hands only, to avoid scratching the seal ring.

- Apply Even Force, Prevent Twisting: Press the seal ring slowly and evenly into the groove, ensuring it seats completely without any “twisting” or “rolling.”

- Check Seating: After installation, carefully inspect that the seal ring sits flat and fully in the groove, with no portion protruding or unevenly compressed.

- Maintenance and Replacement:

- Regular Inspection: Inspect the seal ring condition during major system overhauls, focusing on hardness change, compression set, surface cracks, erosion pits, etc.

- Replacement Principle: Even without obvious leaks, preventive replacement is advised if the seal ring has exceeded its recommended service life (typically 3-8 years depending on material and conditions) or if hardness change exceeds a certain range (e.g., ±10 Shore A).

- Seating Surface Maintenance: Each time the seal ring is replaced, inspect and polish the valve seat sealing surface to ensure its finish (typically Ra ≤ 0.8 μm), removing old compression marks and corrosion spots.

Conclusion

The seal ring for the valve disc of a seawater makeup water system interconnecting valve, though a small component, is the “gatekeeper” ensuring the safe, efficient, and stable operation of large industrial systems. Its full performance relies on appropriate material selection for the conditions, high-performance products based on rigorous design, and standardized, meticulous installation and maintenance. With the growing development of marine engineering today, continuously optimizing the material technology, structural design, and application practices of seal rings holds significant practical importance for enhancing the reliability and economy of entire systems.

Post time: Dec-23-2025