The Star Seal Ring (X-Ring or Quad-Ring) is a high-performance sealing element widely used for reciprocating motion in modern hydraulic and pneumatic systems. Its unique design delivers superior sealing performance in numerous applications.

1. Core Structure Analysis

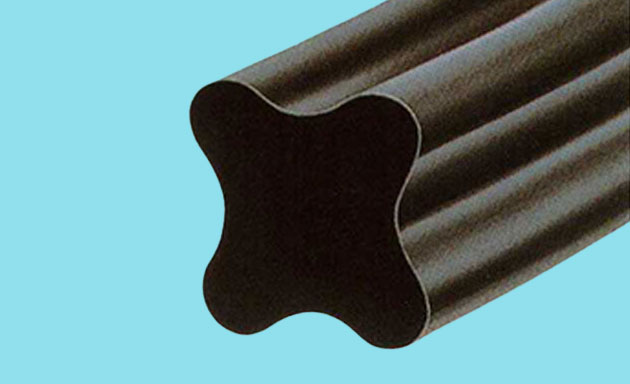

The Star Seal Ring derives its name from its cross-sectional characteristics. As shown in Figure 1, its cross-section forms four symmetrically distributed sealing lips, resulting in a distinct “star” or “X” shape. Unlike the simple circular cross-section of an O-ring, its structural features include:

- Four-Lip Design: Creates four sealing lips (top, bottom, left, right) upon installation in a groove.

- Internal Cavity: A relatively enclosed cavity structure exists in the center of the cross-section.

- Groove Compatibility: Its design is compatible with standard O-ring grooves, often allowing direct replacement of O-rings.

2. Core Advantages of the Star Structure

This sophisticated four-lip structure provides significant performance improvements:

- Exceptional Sealing Reliability:

- Redundant Sealing: Creates multiple sealing barriers; even if a single lip is damaged or a minor leak path forms, the other lips maintain sealing effectiveness.

- Excellent Low-Pressure Sealing: The unique cross-section ensures more uniform contact stress distribution and easier attainment of the initial contact pressure needed for sealing, excelling in low-pressure and even vacuum environments.

- Superior Low Friction and Twist Resistance:

- Uniform Stress Distribution: The four lips share radial loads, resulting in lower unit area contact stress than single-lip seals or O-rings. The internal cavity absorbs compression, preventing excessive squeezing.

- High Twist Resistance: The symmetrical structure offers strong resistance to twisting during dynamic conditions (e.g., uneven loads or radial deflection in hydraulic cylinders), reducing failure risks.

- Reduced Stick-Slip Effect: Smoother friction characteristics help mitigate “stick-slip” during low-speed movement, ensuring smoother motion.

- Good Lubrication Retention:

- The internal cavity stores a small amount of lubricating medium, providing continuous lubrication to the lips, crucial for the lifespan of dynamic seals.

- Excellent Wear Resistance:

- The load is shared among multiple lips, reducing pressure on each lip. Combined with inherently low friction coefficients, overall wear rates are lower.

- Good Extrusion Resistance:

- The compact, sturdy structure resists extrusion into gaps (extrusion failure) better than traditional O-rings, even under high pressure or with larger clearance fits.

3. Comparison with Other Seal Structures

Key performance comparisons between the Star Seal Ring and commonly used O-rings (static/dynamic) and Lip Seals (primary for dynamic sealing):

Table 1: Star Seal Ring (Reciprocating Seal) vs. O-ring & Lip Seal (e.g., U-Cup)

| Performance Indicator | Star Seal Ring (X-Ring) | O-ring | Typical Lip Seal (e.g., U-Cup, Y-Ring) |

|---|---|---|---|

| Sealing Principle | Symmetrical Quadruple-Lip Contact | Radial Compression Face Seal | Asymmetrical Single/Double Lip Seal |

| Friction Resistance | Low to Medium (Symmetrical load sharing) | High (Large contact area) | Low (Line/band contact) |

| Twist Resistance | Excellent (Symmetrical) | Poor (Prone to spiral failure) | Moderate (Can invert/shear) |

| Sealing Reliability | High (Multi-barrier, good low-pressure) | Good (Static)/Moderate (Dynamic) | High (High contact pressure) |

| Wear Resistance | Excellent (Load sharing) | Moderate (Static)/Poor (Dynamic) | Good (Concentrated stress) |

| Extrusion Resistance | Good | Poor | Excellent (Designed w/ backup ring) |

| Applicable Pressure Range | Medium-High (Requires backup ring for VHP) | Low-Medium (Dyn)/High (Stat w/ BR) | Broad (Low to Very High Pressure) |

| Applicable Speed | Medium-High | Low | Medium-High |

| Space Requirement | Similar to O-ring | Smallest | Larger (Groove design critical) |

| Installation | Care w/ lip orientation (Usually non-directional) | Simple | Critical orientation |

| Cost | Moderate to High | Lowest | Moderate |

Main Disadvantages:

- Higher Cost than O-rings: Complex structure increases manufacturing costs.

- Installation Care Required: While not direction-sensitive like lip seals, care is needed to prevent lip damage during installation over sharp edges (requiring guides).

- VHP Requires Backup: Like O-rings, backup rings are needed for optimal extrusion resistance at very high pressures (e.g., >70 MPa).

4. Common Materials and Typical Applications

Material selection is crucial. Primarily used in hydraulic/pneumatic media, common materials include:

- Nitrile Rubber (NBR):

- Properties: Excellent resistance to mineral oil, fuel; good wear resistance & strength; cost-effective; Max Temp: ~100–120°C (grade-dependent); Min Temp: ~-30 to -40°C (grade-dependent); moderate ozone/weather resistance.

- Applications: Most common material. Widely used in industrial hydraulics (construction, injection molding, machine tools), automotive brake systems, pneumatic equipment with mineral oil, HFA/HFB fluids, water-glycol, fuel – where temperature isn’t critical. >70% of X-ring usage.

- Hydrogenated Nitrile Rubber (HNBR):

- Properties: Improves upon NBR: higher heat resistance (+140–150°C), ozone/chemical resistance; better strength & wear; retains NBR oil resistance; higher cost than NBR.

- Applications: For higher temperatures, demanding oils (additive-rich lubricants), or longer life needs. E.g., automotive engine seals, high-performance hydraulics, hot oil systems.

- Fluoroelastomer (FKM, Viton®):

- Properties: Excellent heat resistance (+200–230°C), superior chemical resistance (oils, fuels, mineral acids, solvents); excellent ozone/weather; poor low-temp (-20 to -30°C); high cost; degrades in hot water/steam.

- Applications: High-temp environments (engines, turbines), aggressive fuels, synthetic ester lubricants (e.g., aircraft fluid), acids/bases (non-caustic), special chemicals. Standard for high-temp fluids like phosphate esters.

- Polyurethane Rubber (AU/EU):

- Properties: Very high mechanical strength, exceptional wear resistance; good extrusion resistance; good oil (mineral/fuel) resistance; poor hydrolysis resistance, especially in hot/humid conditions; Max Temp: ~80–110°C (type-dependent).

- Applications: Primarily for high pressure, large gaps, low frequency/impact loads with mineral oil/fuel media. E.g., large cylinder piston seals, high-pressure water systems (short-term). Use cautiously in water-glycol due to hydrolysis.

- Ethylene Propylene Diene Monomer (EPDM):

- Properties: Excellent resistance to hot water, steam, water-glycol, phosphate ester fluids, HFC fluids, dilute acids/bases; excellent ozone/weathering; good polar solvent resistance; poor resistance to mineral oils/fuels; Max Temp: ~150°C.

- Applications: Sealing water, water-glycol, HFC hydraulic fluids, phosphate esters, steam, refrigerants, brake fluid (DOT) – polar fluids. E.g., food processing, marine hydraulics, specific industrial equipment.

- PTFE Blends:

- Properties: Leverages PTFE’s superb chemical inertness, extremely low friction, excellent heat resistance (>260°C). Fillers (bronze, glass fiber, graphite, carbon) enhance strength/conductivity; poor elasticity, difficult installation, prone to cold flow/creep.

- Applications: Extreme conditions: Ultra-high/low temps/pressure, aggressive chemicals, high-purity media (semiconductors, chemical), ultra-low friction (high-speed pneumatics). Often used as backup rings for O-rings; pure PTFE X-rings are rare/expensive.

Conclusion

The Star Seal Ring’s unique symmetrical four-lip structure achieves an excellent balance of friction, sealing reliability, and twist resistance in reciprocating seals. It maintains the O-ring’s compactness and groove compatibility while significantly outperforming it in friction, twist resistance, and low-pressure sealing. Compared to more complex asymmetric lip seals (e.g., U/Y-rings), it excels in twist resistance under symmetrical loads and installation simplicity. Diverse material options cover applications from standard industrial to extreme conditions. Selection requires considering media compatibility, temperature range, pressure, speed, and cost to ensure reliable long-term sealing.

Post time: Aug-04-2025