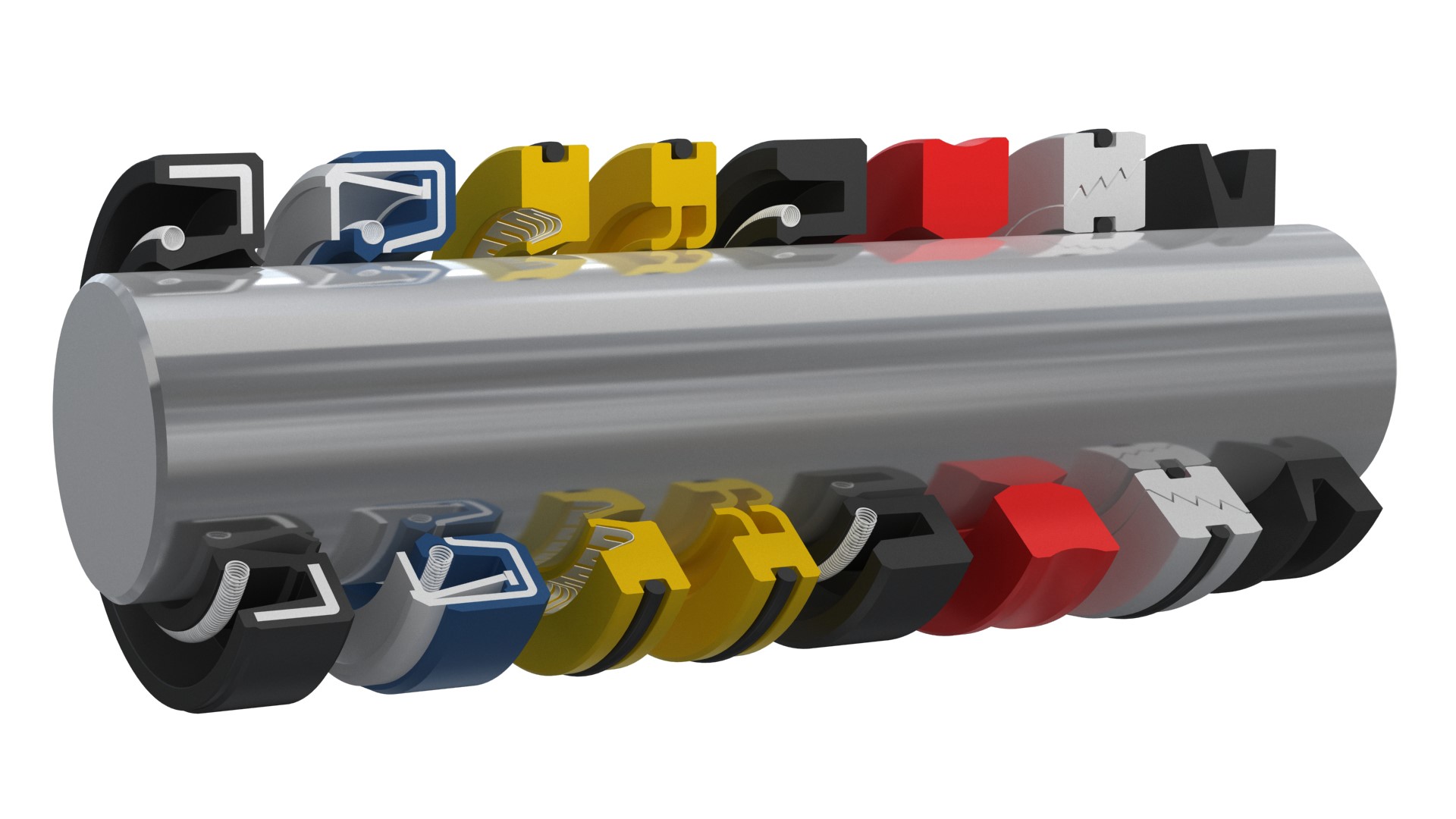

Rolling mill oil seals are indispensable key components in the steel production and metal processing industries. They are primarily used to prevent lubricant leakage, block contaminants from entering the bearing system, and maintain stable equipment operation under high-load, high-speed rotation conditions. In rolling mills such as hot or cold rolling mills, oil seals must withstand extreme conditions, including high temperature, high pressure, water contamination, and mechanical wear. Referring to the provided images, these oil seals typically feature a ring-shaped metal structure with toothed or lip-shaped sealing edges, designed to form a tight dynamic seal. Their design not only affects equipment efficiency but also directly impacts production line reliability and maintenance costs. This article will focus on rolling mill oil seals, exploring their design principles, material selection, working mechanisms, application scenarios, and the latest developments.

Design Principles and Structure

The core design principle of rolling mill oil seals lies in achieving effective sealing between the rotating shaft and the stationary housing while allowing high-speed rotation of the shaft. Typical structures include a housing (usually made of metal or composite materials), a sealing lip (the elastomeric lip portion), and auxiliary components such as springs or support rings. The sealing lip contacts the shaft surface, forming a thin oil film to reduce friction and prevent leakage. According to rotating seal design guidelines, the outer diameter of the oil seal typically forms a gasket-style seal to prevent rust or corrosion.

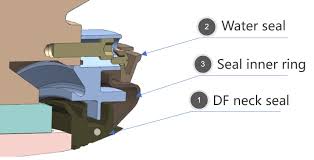

In rolling mill applications, oil seals often adopt V-shaped or lip-type designs, such as the DF neck seal, as shown in some manufacturers’ hot and cold rolling mill drum seals. This design includes water seals, inner rings, and neck seal components, effectively isolating cooling water and lubricating oil. The oil seals in the images display multi-layer ring arrangements, with toothed edges likely used to enhance grip and expel contaminants. Delong Seals’ specialized rolling mill oil seals, through optimized lip geometry, significantly reduce temperature rise and water ingress, improving sealing performance.

Common design types include:

- Single-lip seals: Suitable for standard lubricant sealing, with the lip facing the oil side.

- Double-lip seals: An additional lip is used to exclude external contaminants, such as water or metal chips.

- PTFE lip seals: Used in high-pressure and high-speed environments, capable of withstanding pressures above 10 bar and speeds of 40–45 m/s.

Design considerations include shaft surface finish (recommended Ra 0.2–0.8 μm) and hardness (at least 45 HRC) to minimize wear.

Material Selection

The selection of oil seal materials depends on operating temperature, media compatibility, and wear resistance. The following are common materials and their characteristics:

| Material | Temperature Range | Key Characteristics | Suitable Media | Limitations |

|---|---|---|---|---|

| Nitrile Rubber (NBR) | -65°F to 250°F (-54°C to 121°C) | Oil-resistant, water-resistant, low cost; standard hardness 70 Shore A. | Mineral oil, hydraulic fluids, water. | Not resistant to high temperatures or ozone. |

| Fluorocarbon Rubber (FKM/Viton) | -30°F to 300°F (-34°C to 149°C) | Excellent chemical and high-temperature resistance; high tensile strength. | Fuels, acidic environments, synthetic oils. | Higher cost, not suitable for low temperatures. |

| Silicone Rubber (VMQ) | -90°F to 340°F (-68°C to 171°C) | Wide temperature range, aging-resistant. | Silicone oils, food-grade applications. | Moderate oil resistance, poor wear resistance. |

| Polytetrafluoroethylene (PTFE) | -90°C to 260°C | Extremely low friction, high-pressure resistance; suitable for pharmaceutical and food industries. | Extreme chemical environments, high-speed rotation. | Requires hard shaft surfaces, complex installation. |

According to Delong’s oil seal selection guide, NBR is the preferred choice for most rolling mill applications, while FKM is suitable for acidic or high-temperature environments. In steel production, O-rings are often used in combination with oil seals, with materials such as NBR employed in pump and valve systems to maintain pressure and prevent leakage. Viton offers the broadest chemical compatibility, making it suitable for refining and rolling mill environments.

Working Principle

The operation of oil seals is based on the principle of dynamic sealing: the sealing lip forms a thin oil layer (approximately 0.0001–0.001 mm) during shaft rotation, preventing leakage through surface tension and viscosity. Simultaneously, lip designs (such as spiral grooves or auxiliary lips) pump back escaping oil and exclude external contaminants. In rolling mills, oil seals must address shaft eccentricity, vibration, and thermal expansion. NOK’s guidelines indicate that oil seals achieve zero leakage through the thin oil layer between the lip and the shaft.

In high-load rolling mills, water contamination is a common challenge. Advanced oil seals reduce the risk of water entering bearings through multi-layer lips and drainage channels, thereby extending equipment lifespan.

Application Scenarios

Rolling mill oil seals are widely used in the steel, paper, and heavy machinery industries. Examples include:

- Hot/cold rolling mills: Sealing drum bearings to prevent cooling water from mixing with lubricating oil.

- Pumps and gearboxes: Sealing hydraulic systems at rotating shafts.

- Large drums: Such as continuous rolling lines in steel plants, enduring high speeds (up to 45 m/s) and pressure.

According to a YouTube introduction to rotary seals, oil seals are used in extreme environments such as submarines, wind turbines, and steel mills. In the Industry 4.0 era, smart oil seals integrated with sensors monitor leakage and temperature, further enhancing reliability.

Maintenance and Innovation

Maintenance includes regular inspections of lip wear, shaft surface condition, and installation alignment. Delong’s design guidelines recommend avoiding stretching during installation in rotary applications to prevent lip stress. Common failures, such as leakage, often stem from material incompatibility or improper installation.

In terms of innovation, Delong’s latest products focus on low friction and high durability, reducing energy consumption. Future trends include nano-coatings and sustainable materials to meet environmental requirements.

Conclusion

As a model of precision engineering, rolling mill oil seals play a crucial role in ensuring the efficient operation of industrial equipment. Through optimized design and material selection, such as NBR or FKM, these seals can withstand harsh environments. Referring to the typical structures in the images, understanding their toothed designs aids in practical applications. In the future, with advancements in materials science, oil seals will further enhance the sustainability and efficiency of steel production.

Rolling mill oil seals are indispensable key components in the steel production and metal processing industries. They are primarily used to prevent lubricant leakage, block contaminants from entering the bearing system, and maintain stable equipment operation under high-load, high-speed rotation conditions. In rolling mills such as hot or cold rolling mills, oil seals must withstand extreme conditions, including high temperature, high pressure, water contamination, and mechanical wear. Referring to the provided images, these oil seals typically feature a ring-shaped metal structure with toothed or lip-shaped sealing edges, designed to form a tight dynamic seal. Their design not only affects equipment efficiency but also directly impacts production line reliability and maintenance costs. This article will focus on rolling mill oil seals, exploring their design principles, material selection, working mechanisms, application scenarios, and the latest developments.

Oil Seals

Design Principles and Structure

The core design principle of rolling mill oil seals lies in achieving effective sealing between the rotating shaft and the stationary housing while allowing high-speed rotation of the shaft. Typical structures include a housing (usually made of metal or composite materials), a sealing lip (the elastomeric lip portion), and auxiliary components such as springs or support rings. The sealing lip contacts the shaft surface, forming a thin oil film to reduce friction and prevent leakage. According to rotating seal design guidelines, the outer diameter of the oil seal typically forms a gasket-style seal to prevent rust or corrosion.

In rolling mill applications, oil seals often adopt V-shaped or lip-type designs, such as the DF neck seal, as shown in some manufacturers’ hot and cold rolling mill drum seals. This design includes water seals, inner rings, and neck seal components, effectively isolating cooling water and lubricating oil. The oil seals in the images display multi-layer ring arrangements, with toothed edges likely used to enhance grip and expel contaminants. Delong Seals’ specialized rolling mill oil seals, through optimized lip geometry, significantly reduce temperature rise and water ingress, improving sealing performance.

Common design types include:

Single-lip seals: Suitable for standard lubricant sealing, with the lip facing the oil side.

Double-lip seals: An additional lip is used to exclude external contaminants, such as water or metal chips.

PTFE lip seals: Used in high-pressure and high-speed environments, capable of withstanding pressures above 10 bar and speeds of 40–45 m/s.

Design considerations include shaft surface finish (recommended Ra 0.2–0.8 μm) and hardness (at least 45 HRC) to minimize wear.

Rolling Mill Oil Seals

Material Selection

The selection of oil seal materials depends on operating temperature, media compatibility, and wear resistance. The following are common materials and their characteristics:

Material

Temperature Range

Key Characteristics

Suitable Media

Limitations

Nitrile Rubber (NBR)

-65°F to 250°F (-54°C to 121°C)

Oil-resistant, water-resistant, low cost; standard hardness 70 Shore A.

Mineral oil, hydraulic fluids, water.

Not resistant to high temperatures or ozone.

Fluorocarbon Rubber (FKM/Viton)

-30°F to 300°F (-34°C to 149°C)

Excellent chemical and high-temperature resistance; high tensile strength.

Fuels, acidic environments, synthetic oils.

Higher cost, not suitable for low temperatures.

Silicone Rubber (VMQ)

-90°F to 340°F (-68°C to 171°C)

Wide temperature range, aging-resistant.

Silicone oils, food-grade applications.

Moderate oil resistance, poor wear resistance.

Polytetrafluoroethylene (PTFE)

-90°C to 260°C

Extremely low friction, high-pressure resistance; suitable for pharmaceutical and food industries.

Extreme chemical environments, high-speed rotation.

Requires hard shaft surfaces, complex installation.

According to Delong’s oil seal selection guide, NBR is the preferred choice for most rolling mill applications, while FKM is suitable for acidic or high-temperature environments. In steel production, O-rings are often used in combination with oil seals, with materials such as NBR employed in pump and valve systems to maintain pressure and prevent leakage. Viton offers the broadest chemical compatibility, making it suitable for refining and rolling mill environments.

Working Principle

The operation of oil seals is based on the principle of dynamic sealing: the sealing lip forms a thin oil layer (approximately 0.0001–0.001 mm) during shaft rotation, preventing leakage through surface tension and viscosity. Simultaneously, lip designs (such as spiral grooves or auxiliary lips) pump back escaping oil and exclude external contaminants. In rolling mills, oil seals must address shaft eccentricity, vibration, and thermal expansion. NOK’s guidelines indicate that oil seals achieve zero leakage through the thin oil layer between the lip and the shaft.

In high-load rolling mills, water contamination is a common challenge. Advanced oil seals reduce the risk of water entering bearings through multi-layer lips and drainage channels, thereby extending equipment lifespan.

Application Scenarios

Rolling mill oil seals are widely used in the steel, paper, and heavy machinery industries. Examples include:

Hot/cold rolling mills: Sealing drum bearings to prevent cooling water from mixing with lubricating oil.

Pumps and gearboxes: Sealing hydraulic systems at rotating shafts.

Large drums: Such as continuous rolling lines in steel plants, enduring high speeds (up to 45 m/s) and pressure.

According to a YouTube introduction to rotary seals, oil seals are used in extreme environments such as submarines, wind turbines, and steel mills. In the Industry 4.0 era, smart oil seals integrated with sensors monitor leakage and temperature, further enhancing reliability.

Maintenance and Innovation

Maintenance includes regular inspections of lip wear, shaft surface condition, and installation alignment. Delong’s design guidelines recommend avoiding stretching during installation in rotary applications to prevent lip stress. Common failures, such as leakage, often stem from material incompatibility or improper installation.

In terms of innovation, Delong’s latest products focus on low friction and high durability, reducing energy consumption. Future trends include nano-coatings and sustainable materials to meet environmental requirements.

Conclusion

As a model of precision engineering, rolling mill oil seals play a crucial role in ensuring the efficient operation of industrial equipment. Through optimized design and material selection, such as NBR or FKM, these seals can withstand harsh environments. Referring to the typical structures in the images, understanding their toothed designs aids in practical applications. In the future, with advancements in materials science, oil seals will further enhance the sustainability and efficiency of steel production.

Post time: Feb-04-2026