In the design of spring-energized seals (often known by names like Fǔnsāi Fēng), the core driving force behind their exceptional performance is not the seal body itself, but its indispensable internal component – the precisely engineered core spring. It bestows upon spring-energized seals their unique advantages in reliability that surpass traditional sealing solutions. This article delves into the structure, materials, and core functions of the spring within a spring-energized seal.

I. Structure of the Spring: A Precisely Engineered Power Source

The spring inside a spring-energized seal is not a conventional compression or extension spring. It is a specially designed structure to provide continuous, uniform radial force:

- 1.Basic Form: U-Shape or V-Shape:

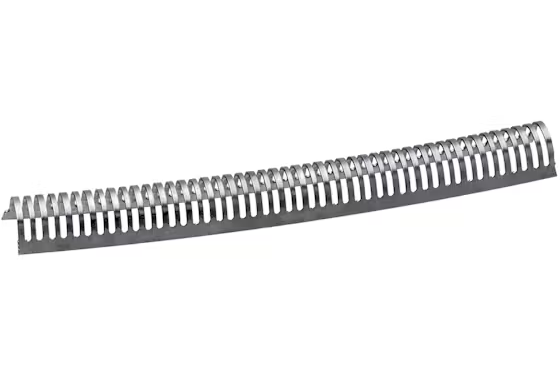

- •U-Shaped Spring (Horseshoe): This is the most classic and widely used structure. Its open U-shape design provides excellent elasticity and recovery capability.

- •V-Shaped Spring: Similar to the U-shape but with a sharper bend (V-shape), it can provide a higher initial spring force, often used in applications requiring greater preload.

- 2.Core Functional Features:

- •Pre-compressed Design: The spring is manufactured in a pre-compressed state before being inserted into the seal body groove. This is the foundation for its ability to provide continuous force.

- •Closed-Loop Ring Structure: The U/V structure is joined end-to-end (typically by precision welding or special joining), forming a complete ring. This ensures the radial force applied to the seal body is highly uniform and continuous around its circumference, with no weak points.

- •Matched to Seal Body Groove: The spring is precisely embedded into a specifically designed groove on the inner side of the seal base body (usually a polymer like PTFE), forming an efficient integrated unit with it.

II. Spring Materials: Selection Under Stringent Demands

Positioned at the heart of the seal and potentially exposed to harsh conditions like pressure, temperature, and corrosive media, the spring material must possess specific properties:

- 1.Core Requirements:

- •High Elasticity & Excellent Fatigue Resistance: Must withstand millions, or even billions, of compression-release cycles without permanent deformation or fracture, ensuring long-term stability of the sealing force.

- •Corrosion Resistance: Ability to resist attack from the sealed media, environment, and potential cleaning agents. Crucial for chemical, pharmaceutical, and food industries.

- •High-Temperature Stability: The material must retain its elasticity and strength without significant degradation within the operating temperature range. Especially critical for applications involving steam, hot oil, etc.

- •Low Creep/Anti-Stress Relaxation: Strong resistance to permanent plastic deformation under sustained stress, preventing the sealing force from diminishing over time.

- 2.Common Materials:

- •Austenitic Stainless Steels: The most common choice, offering a good balance of properties.

- •AISI 304 (1.4301): General purpose, suitable for moderate corrosion environments and medium temperatures.

- •AISI 316/316L (1.4401/1.4404/1.4435): The predominant choice. Molybdenum content significantly enhances pitting and intergranular corrosion resistance, broadening its application range, especially in chemical, marine, food, and pharmaceutical sectors.

- •High-Temperature/High-Performance Alloys: Used for extreme conditions.

- •Inconel X-750 / 718: Nickel-based superalloys offering exceptional high-temperature strength, creep resistance, and relaxation resistance, along with corrosion resistance. Used in aerospace, high-temperature well equipment, etc.

- •Elgiloy/Phynox: Cobalt-chromium-nickel alloys characterized by very high strength, unmatched fatigue resistance, excellent corrosion resistance, and outstanding relaxation resistance. The top choice for long-life, high-reliability demands (e.g., nuclear seals).

- •Hastelloy Alloys: Primarily used for extremely corrosive environments (strong acids, halogens).

- •Austenitic Stainless Steels: The most common choice, offering a good balance of properties.

III. The Core Function of the Spring: An Irreplaceable Driving Force

The internal spring in a spring-energized seal is far from a supporting player; it performs critical tasks that determine the entire sealing performance:

- 1.Provides Constant Initial Sealing Force (Key Differentiator):

- •This is the core advantage over traditional O-rings or lip seals.

- •When the equipment is not yet running, or when the system is at zero/low pressure, the spring’s own preload continuously and steadily exerts an outward radial force. This drives the sealing lip of the seal body to tightly conform against the mating surfaces (shaft/rod and bore/housing wall).

- •Effect: Perfectly solves “dry running” issues during startup and ensures leak-free startup and reliability at low pressures.

- 2.Compensates for System Pressure Fluctuations and Loss:

- •When system pressure increases, the medium pressure helps push the sealing lip into tighter contact.

- •However, when system pressure drops, fluctuates, or disappears (e.g., shutdown, pressure surges), the spring’s constant force immediately “steps in” to compensate for the lack of pressure.

- •Effect: Maintains effective sealing contact force across all operating conditions, preventing leaks during pressure changes or shutdowns. This is fundamental to the reliability of dynamic seals.

- 3.Compensates for Seal Body Wear and Plastic Deformation:

- •The seal body (especially PTFE types) experiences slight wear on the contact face over time, and the material itself may undergo minor permanent deformation (cold flow, creep).

- •The spring acts like a tireless “energy reservoir.” Its inherent resilience continuously follows up, pushing the seal body to fill these microscopic gaps and deformations.

- •Effect: Significantly extends the seal’s service life by maintaining sealing effectiveness long-term.

- 4.Ensures Uniform and Continuous Sealing Force Distribution:

- •Its closed-loop ring structure design ensures that the radial force applied to the seal body is highly uniform, creating a 360-degree seal with no weak points.

- •Effect: Prevents localized accelerated wear or leakage paths caused by uneven sealing force. Particularly beneficial for applications with out-of-roundness or slight surface runout.

Conclusion: The True Power Source

The performance hallmarks of spring-energized seals – long life, low leakage, wide pressure capability, high-temperature resistance – are fundamentally underpinned by their internal precision spring. It transcends the limitations of relying solely on system pressure or the seal body’s inherent elasticity, providing an active, continuous, and adaptive core driving force. The structural design, material selection, and quality control of the spring directly determine the ultimate performance limits and application scope of the seal. Understanding and valuing this “core engine” is key to the correct selection and application of spring-energized seals.

Post time: Aug-11-2025