Ròn inneal-glanaidh JA Hydraulic Sorcadair Wiper

♠ Tuairisgeul - JA Wiper Seal

Tha JA Wiper Seal airson casg a chuir air duslach, salachar, gainmheach no càin a dhol a-steach.Faodar seo a choileanadh le dealbhadh sònraichte a dhìonas na pàirtean stiùiridh gu mòr agus a leudaicheas beatha nan ròin.A bharrachd air an sin, chan fheum stàladh ròn wiper JA sgriothan fàinne no camagan.Chan eil fulangas teann agus cuir a-steach meatailt san riatanas.Is e lùb leantainneach a th’ ann an cearcall wiper agus tha e air leth furasta a chuir a-steach don groove.Mar sin, bu chòir cùl an fhàinne duslach a bhith air a dhìon bho chuideam.

Raon Iarrtais

| Brùthadh [MPa | Teòthachd [ ℃] | Astar sleamhnachaidh[m/s] | Meadhanach | ||||

| Inbhe | -35...+100 | 1 | Ola uisgeach (stèidhichte air ola mèinnearach) | ||||

♣ Buannachd

Bidh ròn fàinne caitheamh a ’toirt seachad stiùireadh agus taic airson piston agus slat piston an t-siolandair uisgeachaidh.A bharrachd air a bhith a 'gabhail a-steach luchdan taobhach.Aig an aon àm, faodaidh e casg a chuir air conaltradh meatailt eadar pàirtean gluasadach an t-siolandair agus coileanadh an t-siostam ròin a bharrachadh.

Is e an inneal-nigheadaireachd, gasket an ròn meacanaigeach a lìonas an àite eadar dà uachdar suirghe no barrachd, mar as trice gus casg a chuir air aodion bho no a-steach do na stuthan ceangailte fhad ‘s a tha iad fo dhlùthadh.

Faodaidh gasgaidean airson tagraidhean sònraichte, leithid siostaman smùid àrd-bhruthadh, a bhith ann an asbestos.Ach, mar thoradh air na cunnartan slàinte co-cheangailte ri foillseachadh asbestos, nuair a tha e practaigeach, tha sinn a’ cleachdadh stuthan gasket neo-asbestos.

Stuth

| Inbhe | PU | |||||

| Sònraichte (air iarrtas) | FKM | |||||

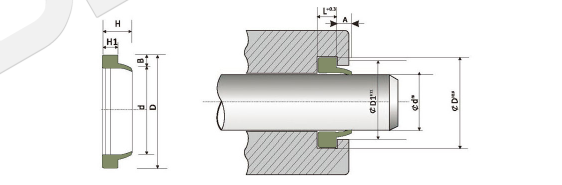

Sònrachadh

| Sònrachadh | Meud groove | ||||||

| Dhf8 | DH10 | D1H11 | L+03 | A | |||

| 14-22.5-4/7 | 14 | 22.5 | 19 | 4 | 3 | ||

| 16-24-5/9 | 16 | 24 | 21 | 5 | 3 | ||

| 16-24.5-4/7 | 16 | 24.5 | 21 | 4 | 3 | ||

| 18-28-5/9 | 18 | 28 | 23 | 5 | 3 | ||

| 18-28.5-5/9 | 18 | 28.5 | 23 | 5 | 3 | ||

| 20-30-5/9 | 20 | 30 | 25 | 5 | 3 | ||

| 20-30.5-5/9 | 20 | 30.5 | 25 | 5 | 3 | ||

| 22-30-5/9 | 22 | 30 | 27 | S | 3 | ||

| 22-32-5/9 | 22 | 32 | 27 | 5 | 3 | ||

| 22-32-5/8.5 | 22 | 32 | 27 | 5 | 3 | ||

| 22-32.25-5/9 | 22 | 32.5 | 27 | 5 | 3 | ||

| 25-34-5/9 | 25 | 34 | 30 | 5 | 3 | ||

| 25-35-5/9 | 25 | 35 | 30 | 5 | 3 | ||

| 25-35.5-5/9 | 25 | 35.5 | 30 | 5 | 3 | ||

| 28-38-5/9 | 28 | 38 | 33 | S | 3 | ||

| 28-38.5-5/9 | 28 | 38.5 | 33 | 5 | 3 | ||

| 30-40-6/10 | 30 | 40 | 36 | 6 | 3 | ||

| 30-40,5-6/10 | 30 | 40.5 | 36 | 6 | 3 | ||

| 32-42-6/10 | 32 | 42 | 38 | 6 | 3 | ||

| 32-42.5-6/10 | 32 | 42.5 | 38 | 6 | 3 | ||

| 35-45-6/10 | 35 | 45 | 41 | 6 | 3 | ||

| 35-45.5-6/10 | 35 | 45.5 | 41 | 6 | 3 | ||

| 36-46.5-6/10 | 36 | 46.5 | 42 | 6 | 3 | ||

| 40-50-6/10 | 40 | 50 | 46 | 6 | 3 | ||

| 40-50,5-6/10 | 40 | 50.5 | 46 | 6 | 3 | ||

| 45-55-6/10 | 45 | 55 | 51 | 6 | 3 | ||

| 45-55,5-6/10 | 45 | 55.5 | 51 | 6 | 3 | ||

| 48-58.5-6/10 | 48 | 58.5 | 54 | 6 | 3 | ||

| 50-60-6/10 | 50 | 60 | 56 | 6 | 3 | ||

| 50-60.5-6/10 | 50 | 60.5 | 56 | 6 | 3 | ||

| 55-65-6/10 | 55 | 65 | 61 | 6 | 3 | ||

| 55-67-7/11 | 55 | 67 | 61 | 7 | 3.5 | ||

| 55-67.5-7/11 | 55 | 67.5 | 61 | 7 | 3.5 | ||

| 56-68.5-7/11 | 56 | 68.5 | 62 | 7 | 3.5 | ||

| 60-72-7/11 | 60 | 72 | 66 | 7 | 3.5 | ||

| 60-72.5-7/11 | 60 | 72.5 | 66 | 7 | 3.5 | ||

| 63-75-7/11 | 63 | 75 | 69 | 7 | 3.5 | ||

| 63-75.5-7/11 | 63 | 75.5 | 69 | 7 | 3.5 | ||

| 65-77-7/11 | 65 | 77 | 71 | 7 | 3.5 | ||

| 65-77.5-7/11 | 65 | 77.5 | 71 | 7 | 3.5 | ||

| 70-82-7/11 | 70 | 82 | 76 | 7 | 3.5 | ||

| 70-82.5-7/11 | 70 | 82.5 | 76 | 7 | 3.5 | ||

| 71-83.5-7/11 | 71 | 83.5 | 77 | 7 | 3.5 | ||

| 72-84.5-7/11 | 72 | 84.5 | 78 | 7 | 3.5 | ||

| 73-85-7/11 | 73 | 8s | 79 | 7 | 3.5 | ||

| 75-87-7/11 | 75 | 87 | 81 | 7 | 3.5 | ||

| 75-87.5-7/11 | 75 | 87.5 | 81 | 7 | 3.5 | ||