In extreme operating environments—including high temperature, high pressure, aggressive chemical exposure, and vacuum conditions—conventional elastomeric seals often prove inadequate. Metallic seals demonstrate superior resilience, with the CA6 Spring-Energized Axial Metallic C-Seal (Open-Top Design) standing as a pinnacle innovation for axial sealing applications across mission-critical industries.

Core Structure & Engineering Features

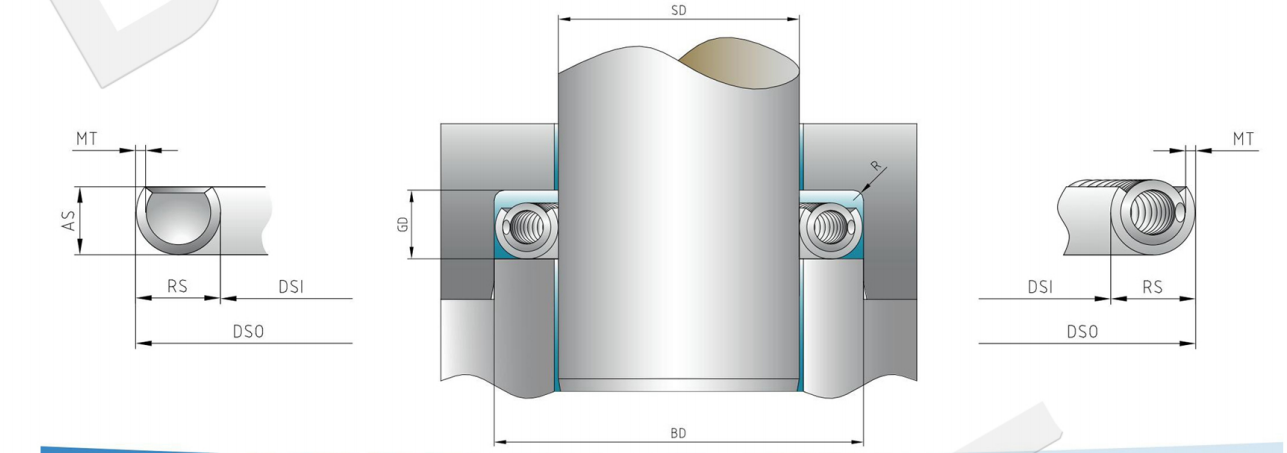

The CA6 seal combines structural rigidity with dynamic compensation:

- C-Shaped Metal Jacket (Open-Top)

- Fabricated from high-performance alloys (e.g., 316L/904L stainless steel, Inconel® 718/X-750)

- Dual-seal mechanism formed by upward-oriented C-cross-section

- Helical Spring Core

- Precision-wound spring delivers constant radial force for operational variance compensation

- Axial Sealing Specialization

- Activated through axial compression via flange bolting

Performance Advantages

| Characteristic | Capability Specification |

|---|---|

| Pressure Resistance | ≤690 bar (10,000 psi) |

| Temperature Range | -250°C to +538°C (Inconel® alloys) |

| Compression Recovery | >90% elastic recovery after 20% crush |

| Corrosion Resistance | NACE MR0175 compliant for sour service |

| Vacuum Integrity | He leak rate ≤1×10⁻⁹ mbar·L/s |

| Radiation Tolerance | Neutron absorption <2.5 barns |

| Service Life | >5 years (200+ thermal cycles) |

Industry Applications

- Energy Sector: BOP stacks (API 16A), nuclear reactor coolant pumps (ASME III)

- Process Industries: Hydrocracking reactors (EN 13445), cryogenic LNG valves

- Advanced Manufacturing: Semiconductor etching chambers (SEMI F37), aero-engine fuel systems

Installation Protocol

- Groove Specification: ASME B16.20 compliant (Ra≤0.8μm)

- Bolt Loading: Torque-angle controlled multi-stage tightening

- Surface Treatment: Application of MoS₂-based lubricant (film thickness ≤50μm)

Post time: Jul-22-2025