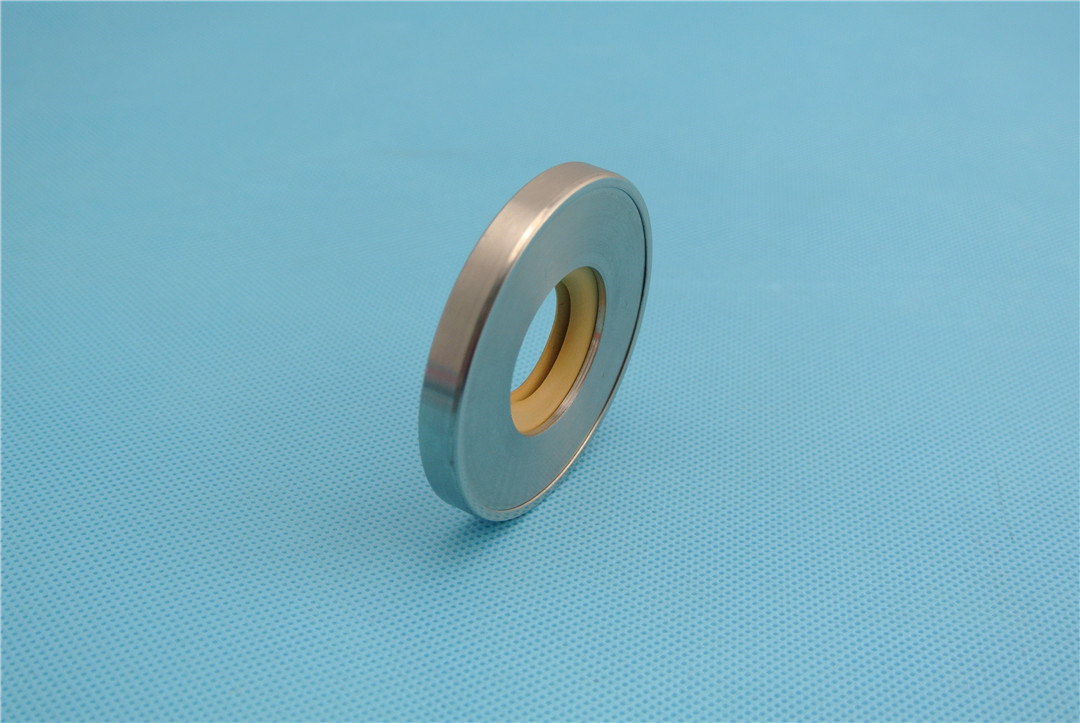

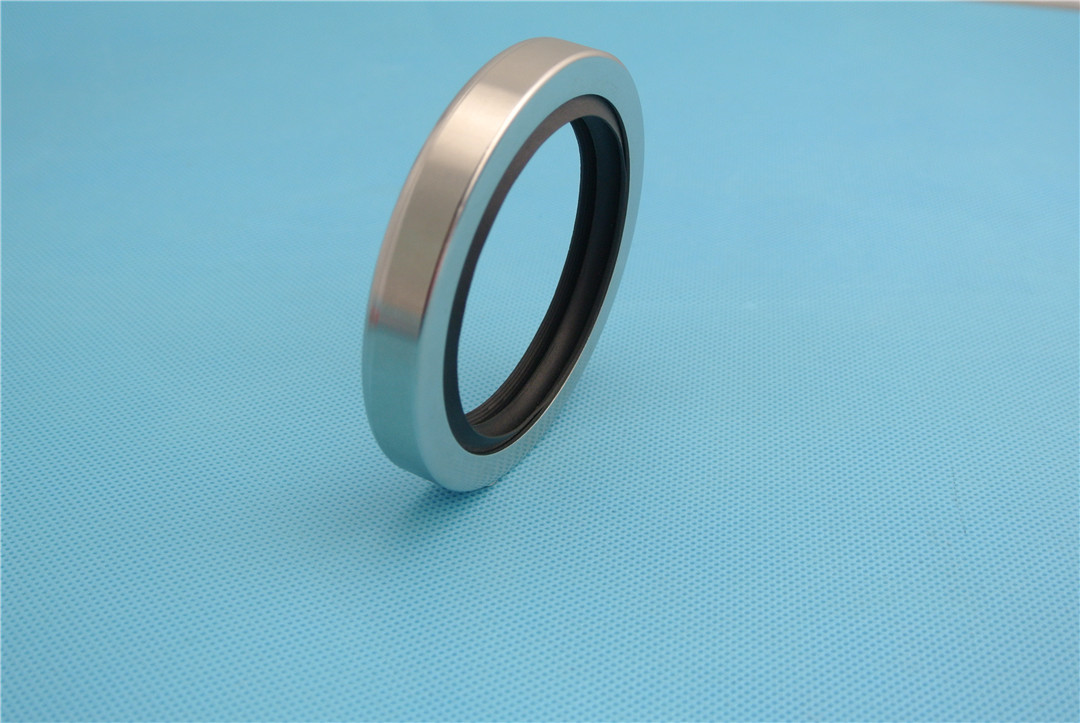

Spring Energzied Seals is a high performance seal with a special spring inside a U-shaped PTFE.

The appropriate spring force combined with the system fluid pressure gently presses the sealing lip (face) out against the metal face to produce a very good seal. The actuation effect of the spring overcomes the slight eccentricity of the metal mating surface and the wear of the sealing lip, while maintaining the desired sealing performance. Spring Energzied Seals are very effective in a wide range of applications. They are used when good chemical resistance to media is required or when the seal is required to operate at extreme temperatures, and where good compression and squeezing properties are required.

PTFE is a seal material with better chemical resistance than perfluoroelastomer, good heat resistance and can be used in most chemical fluids, solvents, hydraulic fluids and lubricating oils, with minimal swelling for long term sealing performance. The use of temperature range can be from the refrigerant to 300 ℃, pressure from vacuum to ultra-high pressure force 700kg moving speed up to 20m / s, and the spring can be used in response to the different use of the environment, the choice of stainless steel, Elgiloy Hastelloy, so can be applied to a variety of high-temperature corrosive fluid occasions.

Spring Energzied Seals can be made according to AS568A standard O-ring groove (such as radial shaft seal, piston seal, axial face seal, etc.), completely replacing the general O-ring, because there is no trouble of expansion, so it can maintain good sealing performance for a long time. For example, the most common cause of leakage in mechanical shaft seals used in petrochemical processes is not only the uneven wear of sliding rings, but also the deterioration and damage of O-rings.

In addition to the above-mentioned sealing applications in high temperature and corrosive environments, Spring Energzied Seals is very suitable for sealing pneumatic cylinders, replacing U- or V-shape compression to achieve excellent sealing performance and service life due to its low friction coefficient of sealing lip, stable sealing contact pressure, high pressure resistance, and tolerance of large radial run-out and groove size error.

Spring Energzied Seals installation guide:

Spring Energzied Seals should only be installed in open grooves.

For a concentric and stress-free fit, follow the steps below.

1. Place the seal in the open groove.

2. Fit the cap, without tightening it first.

3. install the shaft.

4. Fix the cap on the body.

Applications:

Spring Energzied Seals are special seals developed for high temperature corrosive, difficult lubrication and low friction applications. The combination of different PTFE composites, high grade engineering plastics and corrosion resistant metal springs are perfectly suited to meet the increasingly demanding and diverse needs of industry, typical applications are as follows.

1. axial seals for loading and unloading arm rotary joints.

2. Seals for paint spray valves or other paint systems.

3. Seals for vacuum pumps.

4. Seals for beverage, water and beer filling equipment (e.g. filling valves) and the food industry.

5. Seals for the automotive and aerospace industries, such as power steering.

6. Seals for metering equipment (low friction, long life).

7. Seals for other process equipment or pressure vessels.

Sealing principle:

PTFE plate spring combination U-shaped seal (Spring Energzied Seals) by the appropriate spring tension plus the system fluid pressure, the seal lip out and gently press the sealed metal surface to form a very good sealing effect.

Post time: Jun-07-2023