| Application Range | |||||||||||||||||||

| Pressure [MPa] | Temperature [°C] | Sliding speed[m/s] | Medium | ||||||||||||||||

| Standard | 45 | -45...+120 | 1 | Standard hydraulic oils, oil water, water-glycol | |||||||||||||||

| Material | |||||||||||||||

| Elastomer | Slide ring | Support Ring | bearing ring | ||||||||||||

| Standard | NBR/PU | PTFE-Bronze | POM, PA | POM-PTFE-Bronze-Compound | |||||||||||

| Special (on request) | FKM VMQ

EPDM |

PTFE-carbon | POM PA | POM PA | |||||||||||

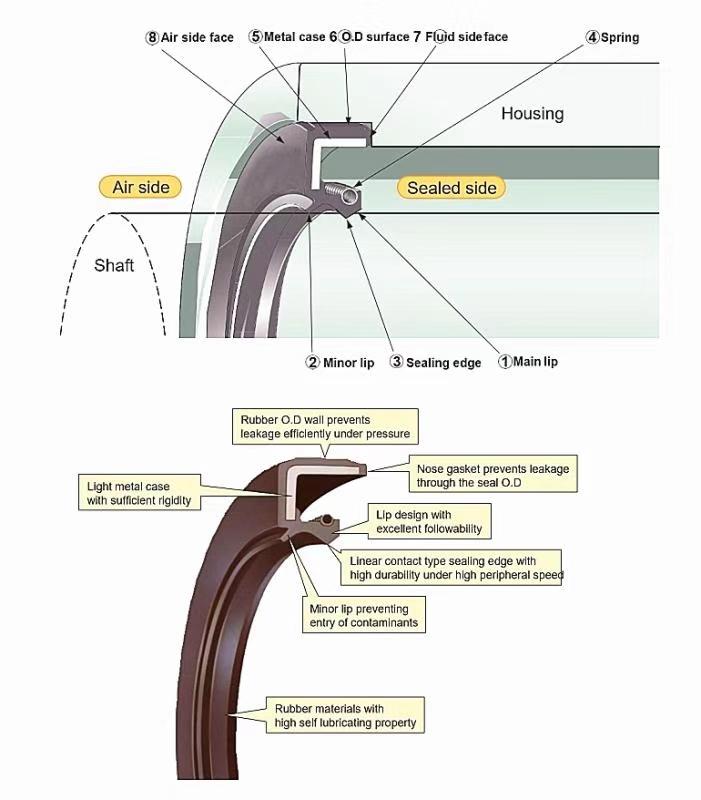

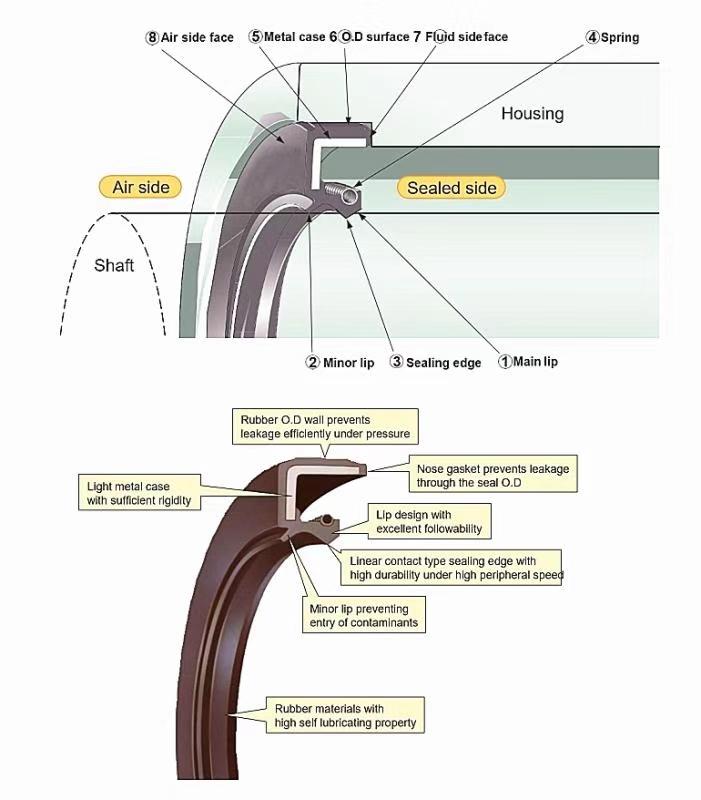

♠Description-TA Oil Seal

The TA oil seal is a mechanical component used to seal oil. TA skeleton oil seal isolates the parts of the transmission component that need to be lubricated from the output components so that lubrication and leakage are not allowed.

This is a rubber-covered double-lip oil seal with a self-tightening spring. Generally speaking, the oil seal often refers to this TA oil seal.

♥Property

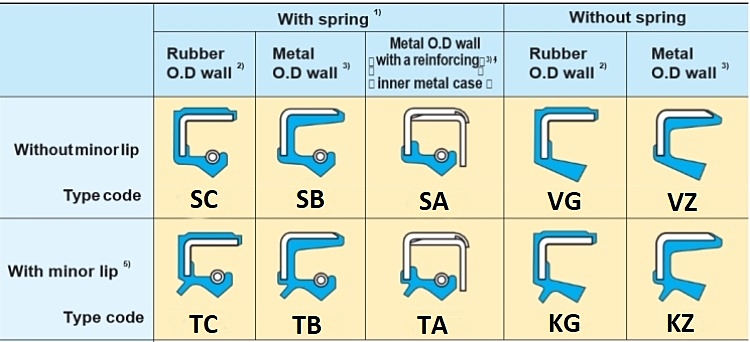

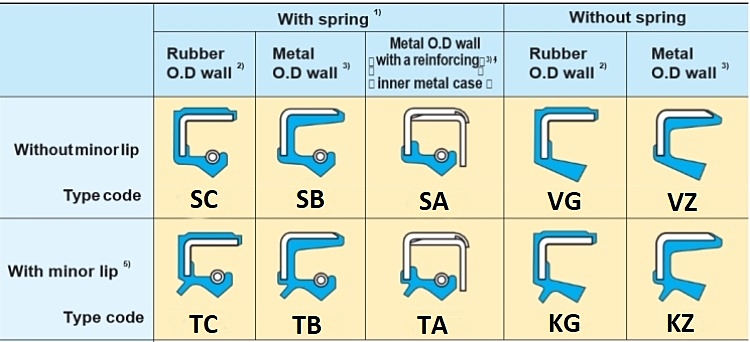

| Type | TC TB TA SC SB SA VC VB VA KC KB KA TCV TCN |

| Temperature | -35~+250℃ |

| Press | 0~0.05MPA |

| Rotational Speed | 0-25m/s |

| Medium | lubricating Oil, Grease, Water |

| Other material of oil seal | Silicone, NBR, Metal & Stainless Steel, PTFE, etc. |

| Production equipment | includes vacuum vulcanizing machines, large-scale flat vacuum vulcanizing machines, |

| rubber machines, CNC machine tools, temperature-controlled ovens, and detectors | |

| Application | High-pressure hydraulic seal auto rubber oil seal |

| 1. Fluid system (static & dynamic) | |

| 2. Hydraulic system (dynamic) | |

| 3. Pneumatic system (dynamic) | |

| 4. Oil or grease media sealing | |

| 5. Water media sealing | |

| 6. automobile, motorcycle, industry, agricultural machinery, truck, buses, trailers, | |

| exercise equipment. |

♣Advantage

♣Advantage

● The structure is simple and easy to manufacture.● Lightweight and low consumables.● The oil seal has a small axial dimension, is easy to machine, and makes the machine compact.● The sealing machine has good performance and long service life.● The oil seal has certain adaptability to the vibration of the machine and the eccentricity of the spindle.● Easy to disassemble and easy to test.

The above specifications are not complete. Besides, we can customize the non-standard parts for you.

Please feel free to contact me if you are interested.

♣Advantage

♣Advantage