BA Blue Rubber Seal Hydraulic Rod Compact Seal

♠Description-BA Symmetric seals

Hydraulic cylinder PARKER BA PU Piston rod Seal

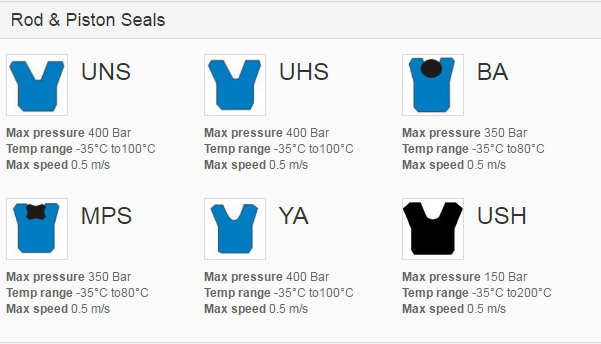

BA Piston Rod Seal is used to seal the shaft, which combines the advantages of BA and BS and adds a supporting ring. The sealing material is imported TPU and CPU, which is resistant to corrosion, high temperature, high pressure and wear.

Application Range

| Pressure [MPa] | Temperature [℃] | Sliding speed[m/s] | Medium | ||||||||||

| Standard Design | 35 | -35...+80 | 0.5 | Hydraulic oils (mineral oil-based) | |||||||||

♣Advantage

● Particularly strong wear resistance.

● Insensitivity to shock loads and pressure peaks.

● High crush resistance.

● It has an ideal sealing effect under no load and low-temperature conditions.

● Suitable for demanding working conditions.

● Easy to install.

Material

| Standard Design | PU/NBR | |||||

| Special (on request) | FKM/NBR | |||||

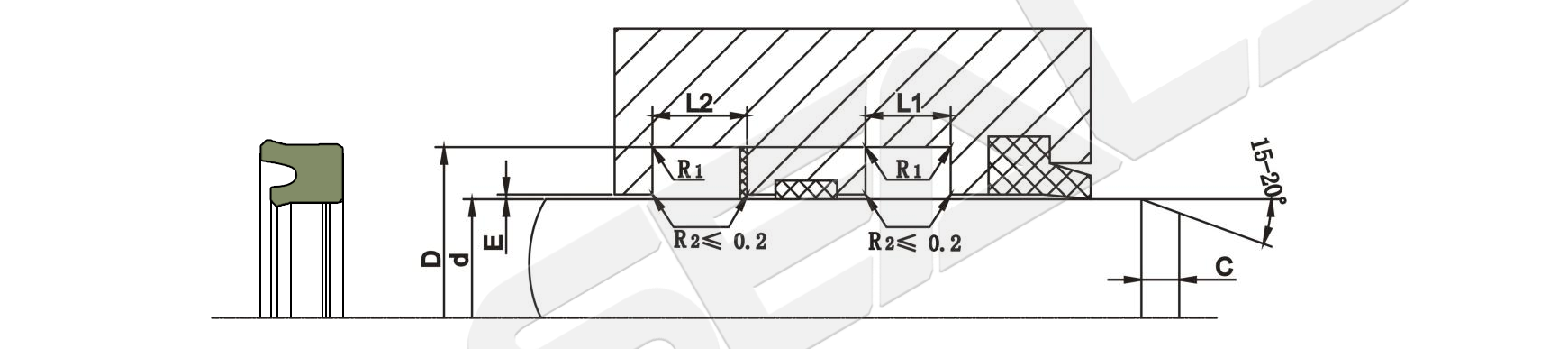

Specification and Groove Size BA

| Specification | Groove size | ||||

| dh9/f8 | DH10 | H | HA+03 | ||

| 3-8.5-4 | 3 | 8.5 | 4 | 4.4 | |

| 4.7-11-5 | 4.7 | 11 | 5 | 5.5 | |

| 4.8-11.1-6.4 | 4.8 | 11.1 | 6.4 | 7 | |

| 6-14-5.7 | 6 | 14 | 5.7 | 6.3 | |

| 6.35-12.7-3.18 | 6.35 | 12.7 | 3.18 | 3.7 | |

| 6.4-12.7-6.4 | 6.4 | 12.7 | 6.4 | 7 | |

| 7.9-14.3-6.4 | 7.9 | 14.3 | 6.4 | 7 | |

| 8-16-5.7 | 8 | 16 | 5.7 | 6.3 | |

| 9.53-15.88-6.35 | 9.53 | 15.88 | 6.35 | 7 | |

| 10-18-5.7 | 10 | 18 | 5.7 | 6.3 | |

| 10-20-7.3 | 10 | 20 | 7.3 | 8 | |

| 11.1-17.5-6.4 | 11.1 | 17.5 | 6.4 | 7 | |

| 12-20-5.7 | 12 | 20 | 5.7 | 6.3 | |

| 12-22-7.3 | 12 | 22 | 7.3 | 8 | |

| 12.7-19.05-4.5 | 12.7 | 19.05 | 4.5 | 5 | |

| 12.7-19.05-4.76 | 12.7 | 19.05 | 4.76 | 5.3 | |

| 12.7-19.05-6.35 | 12.7 | 19.05 | 6.35 | 7 | |

| 12.7-19.1-6.4 | 12.7 | 19.1 | 6.4 | 1 | |

| 12.7-25.4-9.5 | 12.7 | 25.4 | 9.5 | 10.5 | |

| 13-19-4 | 13 | 19 | 4 | 4.4 | |

| 13-20-5 | 13 | 20 | 5 | 5.5 | |

| 13-23-7.3 | 13 | 23 | 7.3 | 8 | |

| 14-22-5.7 | 14 | 22 | 5.7 | 6.3 | |

| 14-24-7.3 | 14 | 24 | 7.3 | 8 | |

| 14.3-20.6-6.4 | 14.3 | 20.6 | 6.4 | 7 | |

| 15-23-5.7 | 15 | 23 | 5.7 | 6.3 | |

| 15.88-22.23-3.18 | 15.88 | 22.23 | 3.18 | 3.7 | |

| 15.9-22.2-4.8 | 15.9 | 22.2 | 4.8 | 5.3 | |

| 15.9-22.2-6.4 | 15.9 | 22.2 | 6.4 | 7 | |

| 16-22.2-4.5 | 16 | 22.2 | 4.5 | 5 | |

| 16-24-5 | 16 | 24 | 5 | 5.5 | |

| 16-24-5.7 | 16 | 24 | 5.7 | 6.3 | |

| 16-25-8 | 16 | 25 | 8 | 8.8 | |

| Specification | Groove size | ||||

| dh9/f8 | DH10 | H | HA+0.3 | ||

| 16-26-7.3 | 16 | 26 | 7.3 | 8 | |

| 17.5-33.3-12.7 | 17.5 | 33.3 | 12.7 | 14 | |

| 18-24-5 | 18 | 24 | 5 | 5.5 | |

| 18-26-5 | 18 | 26 | 5 | 5.5 | |

| 18-26-5.7 | 18 | 26 | 5.7 | 6.3 | |

| 18-28-7.3 | 18 | 28 | 7.3 | 8 | |

| 19-25.4-3.35 | 19 | 25.4 | 3.35 | 3.8 | |

| 19-29-7.3 | 19 | 29 | 7.3 | 8 | |

| 19.05-25.4-3.18 | 19.05 | 25.4 | 3.18 | 3.7 | |

| 19.05-25.4-4.76 | 19.05 | 25.4 | 4.76 | 5.3 | |

| 19.05-25.4-6.35 | 19.05 | 25.4 | 6.35 | 7 | |

| 19.05-31.75-6.25 | 19.05 | 31.75 | 6.25 | 6.9 | |

| 19.1-25.4-4.5 | 19.1 | 25.4 | 4.5 | 5 | |

| 19.1-25.4-6.4 | 19.1 | 25.4 | 6.4 | 1 | |

| 19.1-28.6-7.9 | 19.1 | 28.6 | 7.9 | 8.7 | |

| 20-28-5.5 | 20 | 28 | 5.5 | 6 | |

| 20-28-5.7 | 20 | 28 | 5.7 | 6.3 | |

| 20-28-6.5 | 20 | 28 | 6.5 | 7.2 | |

| 20-30-7.3 | 20 | 30 | 7.3 | 8 | |

| 20-32.7-9.5 | 20 | 32.7 | 9.5 | 10.5 | |

| 20.6-26.8-4.8 | 20.6 | 26.8 | 4.8 | 5.3 | |

| 22-30-5.7 | 22 | 30 | 5.7 | 6.3 | |

| 22-32-7.3 | 22 | 32 | 7.3 | 8 | |

| 22-35-10 | 22 | 35 | 10 | 11 | |

| 22.2-28.6-6.4 | 22.2 | 28.6 | 6.4 | 7 | |

| 22.2-31.8-7.9 | 22.2 | 31.8 | 7.9 | 8.7 | |

| 22.23-28.56-6.35 | 22.23 | 28.56 | 6.35 | 7 | |

| 24-30-5 | 24 | 30 | 5 | 5.5 | |

| 24-32-7 | 24 | 32 | 7 | 7.7 | |

| 24-35-5.7 | 24 | 35 | 5.7 | 6.3 | |

| 25-33-5.7 | 25 | 33 | 5.7 | 6.3 | |

| 25-35-7 | 25 | 35 | 7 | 7.7 | |

| 25-35-7.3 | 25 | 35 | 7.3 | 8 | |

Write your message here and send it to us