DHS Wiper Seal Using poly urethane(PU) as material

♠Description-IDU Rod Seal

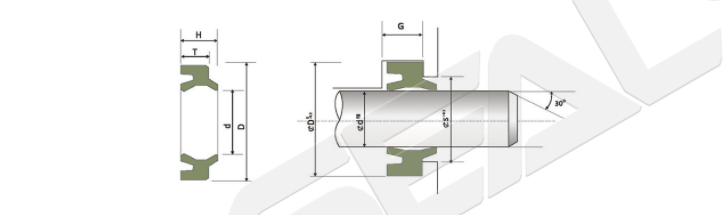

DHS is a seal that prevents dust from entering, protects equipment and maintains sealing performance.Using poly urethane(PU) as material, this is a kind of dust-resistant sealing element for double lip mouth.

DHS Wiper Seal has a double lip seal with a dust lip and an oil seal lip. Its structure makes it excellent in dust resistance and less oil leakage. In addition, The DH/DHS type double lip wiper prevents the entry of dust, dirt, sand and metal chips. Mainly used in hydraulic cylinders and cylinders,The axial movement of the hoist and the guide rod. DHS Wiper Seal is to do reciprocating piston movement.

Application Range

| Pressure[MPa] | Temperature [℃] | Sliding speed[m/s] | Medium | ||||||||||||

| Standard | 35...+100 | 1 | Hydraulic oils (mineral oil-based) | ||||||||||||

♣Advantage

● Insensibility against shock loads and pressure peaks

● High resistance against extrusion

● Sufficient lubrication due to pressure medium between the sealing lips

● Suitable for hardest working conditions

● Easy installation

Material

| Standard Design | PU/NBR | |||||

| Special (on request) | FKM/NBR | |||||

| Standard and /or can fit the groove | ||||||

| JB/ZQ 4265 | ||||||

| GY1 |

Order Example For Standard Version:

| Specification | Groove size | ||||||

| df⁸ | D-0.2 | S±0.1 | G+03 | ||||

| 9-14-3.5/5 | 9 | 14 | 11.6 | 4 | |||

| 10-15-3.8/6.4 | 10 | 15 | 12.6 | 4.3 | |||

| 10-20-4/8 | 10 | 20 | 15 | 4.5 | |||

| 11.2-19.2-4.5/6 | 11.2 | 19.2 | 15.5 | 5 | |||

| 12-16-3/4 | 12 | 16 | 14 | 3.5 | |||

| 12-17-3.2/4,2 | 12 | 17 | 14.6 | 3.7 | |||

| 12-18-2.5/5 | 12 | 18 | 15.3 | 3 | |||

| 12-18-3.6/4.8 | 12 | 18 | 15.3 | 4.1 | |||

| 12-18-3.8/4.8 | 12 | 18 | 15.3 | 4.3 | |||

| 12-18-3.8/6.4 | 12 | 18 | 15.3 | 4.3 | |||

| 12-18-3.9/6 | 12 | 18 | 15.3 | 4.4 | |||

| 12-20-4.5/6* | 12 | 20 | 16.3 | 5 | |||

| 12.5-20.5-4.5/6* | 12.5 | 20.5 | 16.8 | S | |||

| 13-20-5/6.5 | 13 | 20 | 16.5 | 6 | |||

| 14-22-4.5/6* | 14 | 22 | 18.3 | 5 | |||

| 16-22-3.6/4.8 | 16 | 22 | 19.3 | 4.1 | |||

| 16-22-8/10 | 16 | 22 | 19.3 | 9 | |||

| 16-24-4.5/6 | 16 | 24 | 20.3 | 5 | |||

| 16-26-7/9.5 | 16 | 26 | 21 | 8 | |||

| 18-24-3.6/4.8 | 18 | 24 | 21.3 | 4.1 | |||

| 18-26-4.5/6* | 18 | 26 | 22.3 | 5 | |||

| 18-28-4/8 | 18 | 28 | 23 | 4.5 | |||

| 18.5-26-3.214 | 18.5 | 26 | 22.8 | 3.7 | |||

| 19-27-4.5/6* | 19 | 27 | 23.3 | 5 | |||

| 19.05-29.05-5.3/7 | 19.05 | 29.05 | 24.05 | 6.3 | |||

| 20-26-3/6 | 20 | 26 | 23.3 | 3.5 | |||

| 20-26-3.6/4.8 | 20 | 26 | 23.3 | 4.1 | |||

| 20-26-3.6/5 | 20 | 26 | 23.3 | 4.1 | |||

| 20-26-6/8 | 20 | 26 | 23.3 | 7 | |||

| 20-28-4.5/6 | 20 | 28 | 24.3 | 5 | |||

| Specification | Groove size | ||||

| dfs | D-0.2 | S±0.1 | G+03 | ||

| 20-28-5/6.5 | 20 | 28 | 24.3 | 6 | |

| 20-30-7/10 | 20 | 30 | 25 | 8 | |

| 20-32-5/10 | 20 | 32 | 26 | 6 | |

| 22-30-4.5/6* | 22 | 30 | 26.3 | 5 | |

| 22-33.8-2.5/3.5 | 22 | 33.8 | 27.9 | 3 | |

| 22.4-30.4-4.5/6* | 22.4 | 30.4 | 26.7 | 5 | |

| 23.5-31.5-4.5/6 | 23.5 | 31.5 | 27.8 | 5 | |

| 24-32-4.5/6 | 24 | 32 | 28.3 | 5 | |

| 25-30-4.5/6 | 25 | 30 | 27.6 | 5 | |

| 25-31-3.6/5 | 25 | 31 | 28.3 | 4.1 | |

| 25-31-4/6 | 25 | 31 | 28.3 | 4.5 | |

| 25-33-4.5/6 | 25 | 33 | 29.3 | 5 | |

| 25-35-5.3/ | 25 | 35 | 29.3 | 6.3 | |

| 25-36.8-5/8 | 25 | 36.8 | 31.5 | 6 | |

| 26-34-4.5/6 | 26 | 34 | 30.3 | 5 | |

| 27-35-4.5/6* | 27 | 35 | 31.3 | 5 | |

| 28-36-4.5/6* | 28 | 36 | 32.3 | 5 | |

| 28-36-47 | 28 | 36 | 32.3 | 4.5 | |

| 28-39.8-4.5/6 | 28 | 39.8 | 34.5 | 5 | |

| 28-40-5/10 | 28 | 40 | 34.5 | 6 | |

| 29-40-4.5/6.5 | 29 | 40 | 35 | S | |

| 30-38-4/7 | 30 | 38 | 34 | 4.5 | |

| 30-38-4.5/5.8 | 30 | 38 | 34 | 5 | |

| 30-38-4.5/6 | 30 | 38 | 34 | 5 | |

| 30-38-5/6.5 | 30 | 38 | 34 | 6 | |

| 30-40-5/6.5 | 30 | 40 | 35 | 6 | |

| 31.5-39.5-5/6.5 | 31.5 | 39.5 | 35.5 | 6 | |

| 31.75-41.28-5.5/7.5 | 31.75 | 41.28 | 36.75 | 6.5 | |

| 32-40-4.5/5.8 | 32 | 40 | 36 | 5 | |

| 32-40-5/6.5 | 32 | 40 | 36 | 6 | |