LBH Rubber wiper lips Hydraulic Pneumatic Dust Wiper Seal

♠Description-LBH-Dust ring

LBH-Dust ring is a part to remove the dirt, sand, rainwater and frost adhered to the outer surface of the cylinder by the reciprocating piston rod, so as to prevent the external dust and rainwater from entering the inside of the sealing mechanism.

The LBH Wiper Seal/Dust-proof ring is a part to remove dirt, sand, rain, and frost that the reciprocating piston rod adheres to on the external surface of the cylinder to prevent the external dust and rain from entering the inner part of the sealing mechanism. The dust-proof sealing ring is mainly used in one of special sealing parts of steel plant industry.

Application Range

| Pressure[MPa] | Temperature [C] | Sliding speed[m/s] | Medium | |||||||||||||||

| Standard | 15 | NBR:-35...+105 | 0.5 | Hydraulic oils(mineral oil-based) | ||||||||||||||

| FKM:-35 ...+200 | ||||||||||||||||||

♣Advantage

● Insensibility against shock loads and pressure peaks

● High resistance against extrusion

● Sufficient lubrication due to pressure medium between the sealing lips

● Suitable for hardest working conditions

● Easy installation

Material

| Standard | NBR/FKM | ||||||||

| Special (on request) | FKM | ||||||||

Order Example For Standard Version:

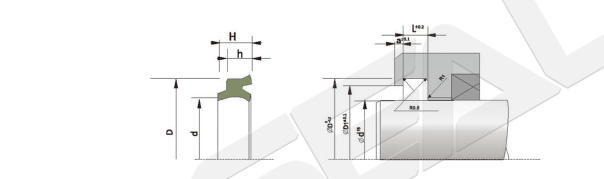

| Specification | Groove size | |||||||||

| df8 | D-0.2 | D1±0.1 | L±0.2 | a±01 | ||||||

| 11.2-19.2-4.5/6 | 11.2 | 19.2 | 15.5 | 5 | 2 | |||||

| 12-20-4.5/6 | 12 | 20 | 16.3 | 5 | 2 | |||||

| 12.5-20.5-4.5/6 | 12.5 | 20.5 | 16.8 | 5 | 2 | |||||

| 14-22-4.5/6 | 14 | 22 | 18.3 | 5 | 2 | |||||

| 16-22-3.2/4 | 16 | 22 | 20.3 | 5 | 2 | |||||

| Specification | Groove size | ||||

| df8 | D-0.2 | D1±0.1 | L±0.2 | a±01 | |

| 16-24-4.5/6 | 16 | 24 | 20.3 | 5 | 2 |

| 18-26-4.5/6 | 18 | 26 | 22.3 | 5 | 2 |

| 20-28-4.5/6 | 20 | 28 | 24.3 | 5 | 2 |

| 22-30-4.5/6 | 22 | 30 | 26.3 | 5 | 2 |

| 22.4-30.4-4.5/6 | 22.4 | 30.4 | 26.7 | 5 | 2 |

| Specification | Groove size | ||||

| df8 | D-0.2 | D1±0.1 | L±0.2 | a±01 | |

| 23.5-31.5-4.5/6 | 23.5 | 31.5 | 27.8 | 5 | 2 |

| 25-33-4.5/6 | 25 | 33 | 29.3 | 5 | 2 |

| 28-36-4.5/6 | 28 | 36 | 32.5 | 5 | 2 |

| 30-38-5/6.5 | 30 | 38 | 34 | 6 | 2 |

| 31.5-39.5-5/6.5 | 31.5 | 39.5 | 35.5 | 6 | 2 |

| 32-40-5/6.5 | 32 | 40 | 36 | 6 | 2 |

| 35-43-5/6.5 | 35 | 43 | 39 | 6 | 2 |

| 35.5-43.5-5/6.5 | 35.5 | 43.5 | 39.5 | 6 | 2 |

| 36-44-5/6.5 | 36 | 44 | 40 | 6 | 2 |

| 38-46-5/6.5 | 38 | 46 | 42 | 6 | 2 |

| 40-48-5/6.5 | 40 | 48 | 44 | 6 | 2 |

| 45-53-5/6.5 | 45 | 53 | 49 | 6 | 2 |

| 48-56-5/6.5 | 48 | 56 | 52 | 6 | 2 |

| 50-58-5/6.5 | 50 | 58 | 54 | 6 | 2 |

| 53-61-5/6.5 | 53 | 61 | 57 | 6 | 2 |

| 55-63-5/6.5 | 55 | 63 | 59 | 6 | 2 |

| 56-64-5/6.5 | 56 | 64 | 60 | 6 | 2 |

| 58-66-5/6.5 | 58 | 66 | 62 | 6 | 2 |

| 60-68-5/6.5 | 60 | 68 | 64 | 6 | 2 |

| 63-71-5/6.5 | 63 | 71 | 67 | 6 | 2 |

| 65-73-5/6.5 | 65 | 73 | 69 | 6 | 2 |

| 67-75-5/6.5 | 67 | 75 | 71 | 6 | 2 |

| 70-80-6/8 | 70 | 80 | 75 | 7 | 3 |

| 71-81-6/8 | 71 | 81 | 76 | 7 | 3 |

| 75-85-6/8 | 75 | 85 | 80 | 7 | 3 |

| 80-90-6/8 | 80 | 90 | 85 | 7 | 3 |

| 85-95-6/8 | 85 | 95 | 90 | 7 | 3 |

| 90-100-6/8 | 90 | 100 | 95 | 7 | 3 |

| 95-105-6/8 | 95 | 105 | 100 | 7 | 3 |

| 98-108-6/8 | 98 | 108 | 103 | 7 | 3 |

| 100-110-6/8 | 100 | 110 | 105 | 7 | 3 |

| 105-115-6/8 | 105 | 115 | 110 | 7 | 3 |

| 106-116-6/8 | 106 | 116 | 111 | 7 | 3 |

| 110-120-6/8 | 110 | 120 | 115 | 7 | 3 |

| 112-122-6/8 | 112 | 122 | 117 | 7 | 3 |

| 115-125-6/8 | 115 | 125 | 120 | 7 | 3 |

| Specification | Groove size | ||||

| df8 | D-0.2 | D1±0.1 | L±0.2 | a±01 | |

| 118-128-6/8 | 118 | 128 | 123 | 7 | 3 |

| 120-130-6/8 | 120 | 130 | 125 | 7 | 3 |

| 125-138-7/9.5 | 125 | 138 | 132 | 8 | 3 |

| 130-143-7/9.5 | 130 | 143 | 137 | 8 | 3 |

| 132-145-7/9.5 | 132 | 145 | 139 | 8 | 3 |

| 136-149-7/9.5 | 136 | 149 | 143 | 8 | 3 |

| 140-153-7/9.5 | 140 | 153 | 147 | 8 | 3 |

| 145-158-7/9.5 | 145 | 158 | 152 | 8 | 3 |

| 150-163-7/9.5 | 150 | 163 | 157 | 8 | 3 |

| 153-165-7/9.5 | 153 | 165 | 160 | 8 | 3 |

| 153-166-7/9.5 | 153 | 166 | 160 | 8 | 3 |

| 155-167-7/9.5 | 155 | 167 | 162 | 8 | 3 |

| 155-168-7/9.5 | 155 | 168 | 162 | 8 | 3 |

| 160-173-7/9.5 | 160 | 173 | 167 | 8 | 3 |

| 165-178-7/9.5 | 165 | 178 | 172 | 8 | 3 |

| 165-179-7/9.5 | 165 | 179 | 172 | 8 | 3 |

| 170-183-7/9.5 | 170 | 183 | 177 | 8 | 3 |

| 175-188-7/9.5 | 175 | 188 | 182 | 8 | 3 |

| 180-190-7/9.5 | 180 | 190 | 187 | 8 | 3 |

| 180-193-7/9.5 | 180 | 193 | 187 | 8 | 3 |

| 190-203-7/9.5 | 190 | 203 | 197 | 8 | 3 |

| 200-213-7/9.5 | 200 | 213 | 207 | 8 | 3 |

| 204-217-7/9.5 | 204 | 217 | 211 | 8 | 3 |

| 205-218-7/9.5 | 205 | 218 | 212 | 8 | 3 |

| 210-223-7/9.5 | 210 | 223 | 217 | 8 | 3 |

| 220-233-7/9.5 | 220 | 233 | 227 | 8 | 3 |

| 224-237-7/9.5 | 224 | 237 | 231 | 8 | 3 |

| 225-238-7/9.5 | 225 | 238 | 232 | 8 | 3 |

| 230-243-7/9.5 | 230 | 243 | 237 | 8 | 3 |

| 240-256-10/13 | 240 | 256 | 248 | 11 | 4 |

| 250-266-10/13 | 250 | 266 | 258 | 11 | 4 |

| 280-296-9/12 | 280 | 296 | 288 | 10 | 4 |

| 310-326-9/12 | 310 | 326 | 318 | 10 | 4 |

| 355-375-10/14 | 355 | 375 | 365 | 11 | 5 |

| 500-520-11.5/15.5 | 500 | 520 | 510 | 12.5 | 5 |